PRODUCTS

-

About Us

- About Us

- About Mechanical Seals

-

Business Segments

-

Our Sealing Technologies and R&D

-

Environmentally friendly products

-

Products

- Products

-

Search by category

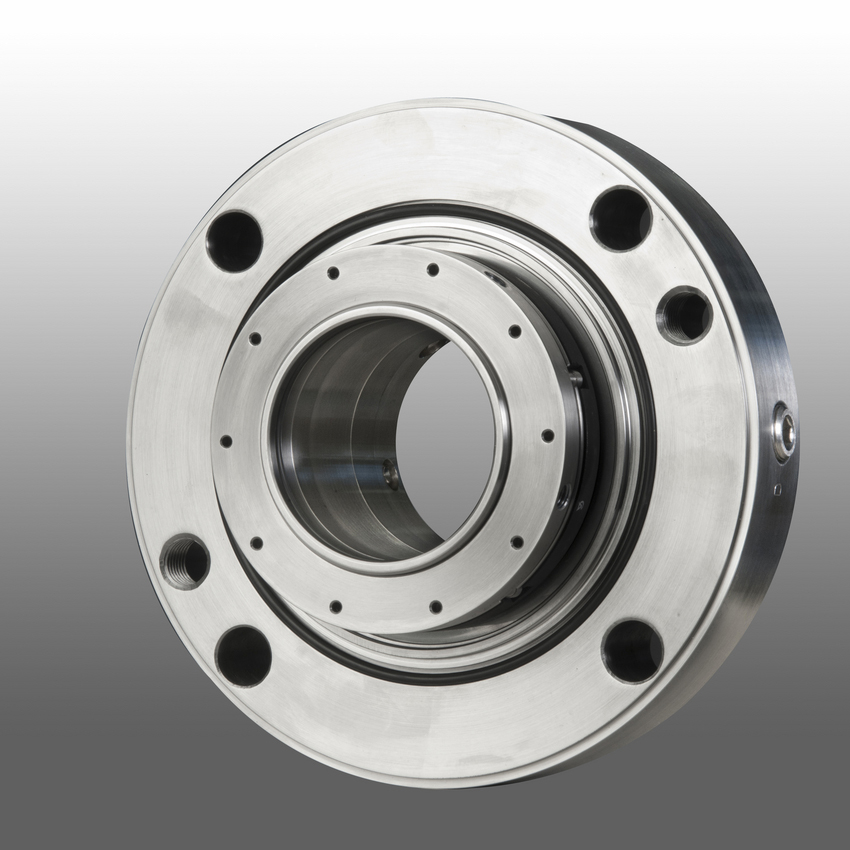

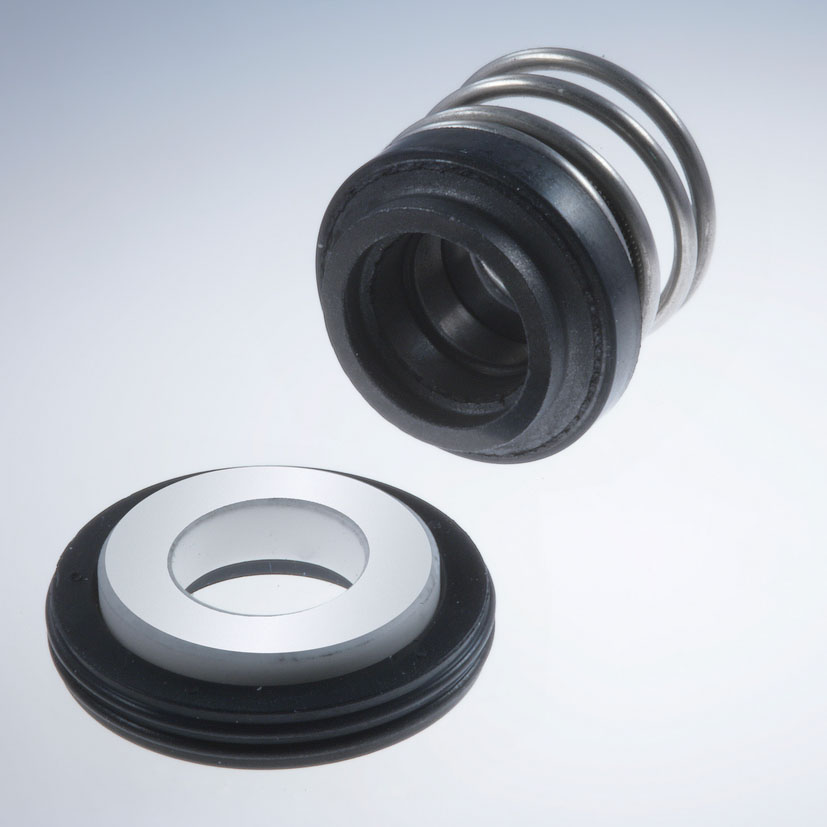

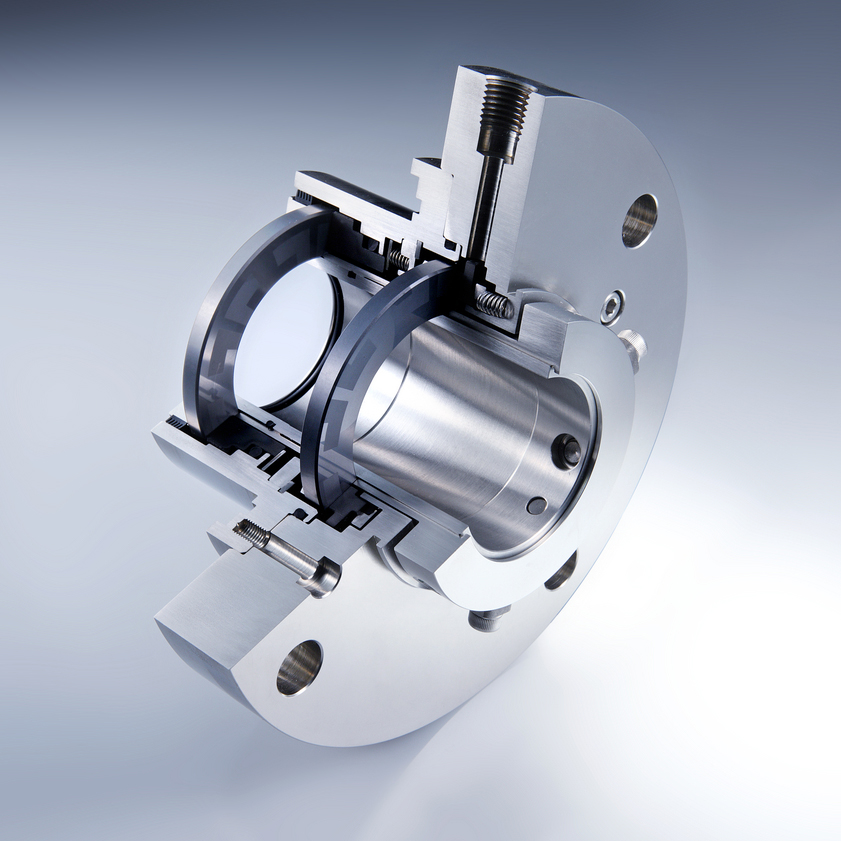

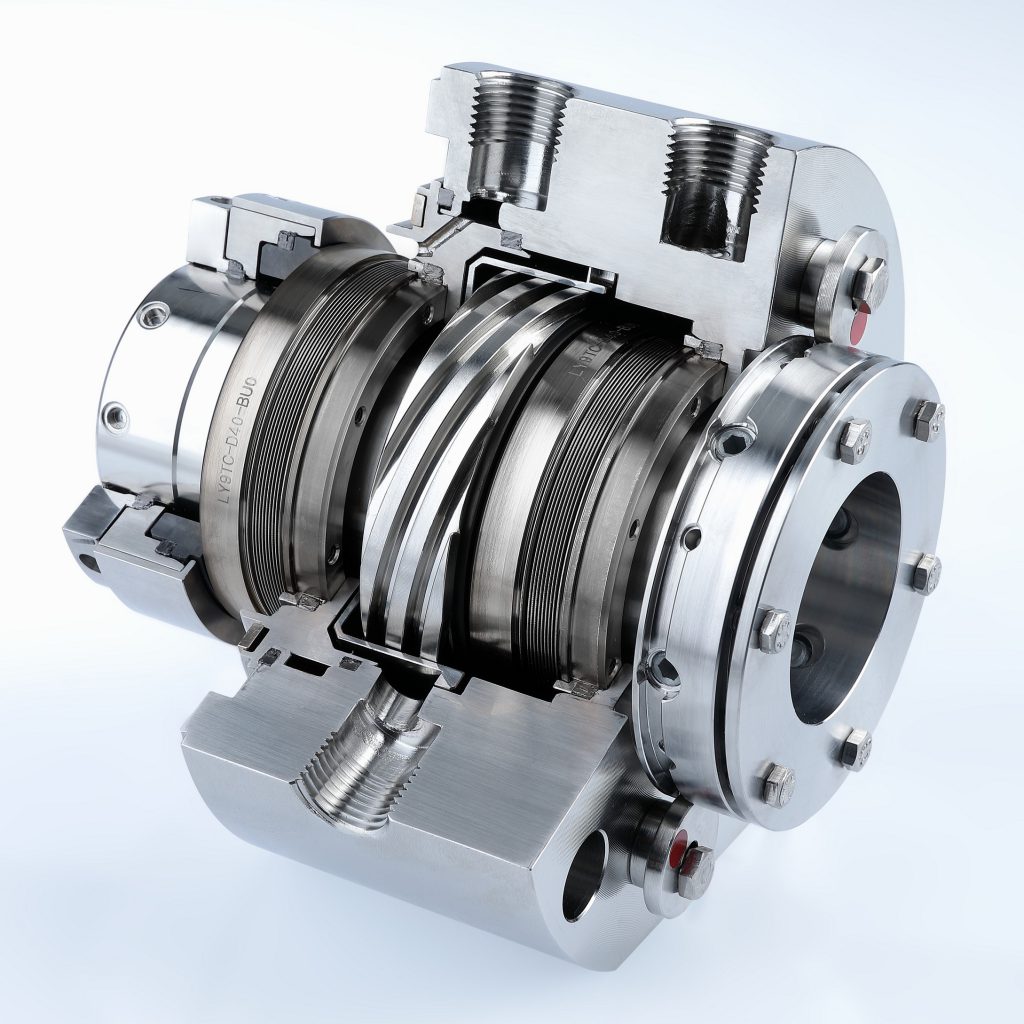

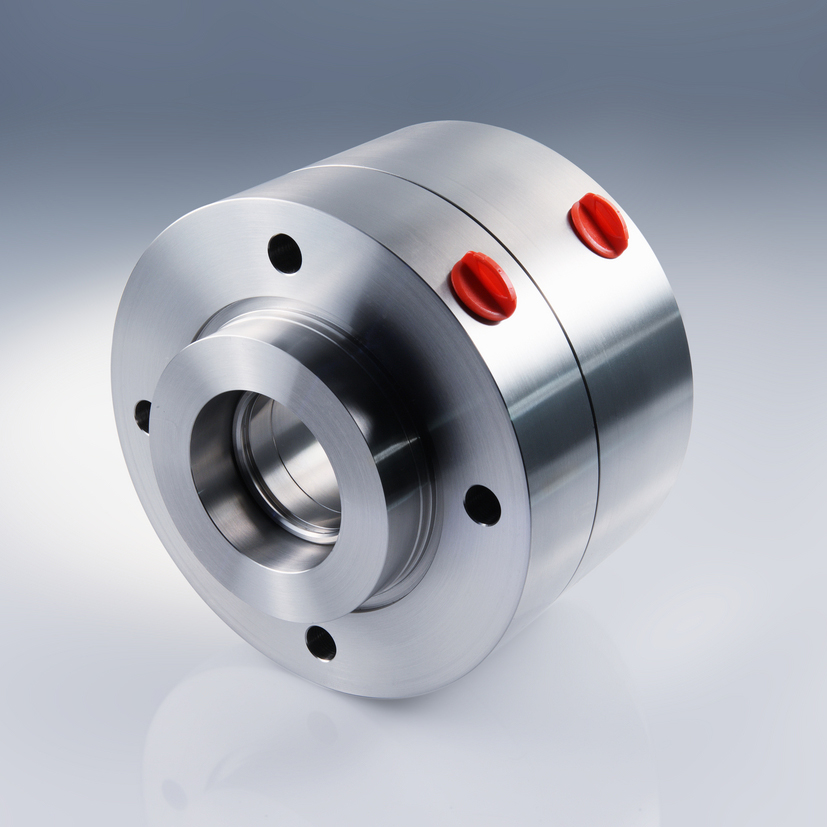

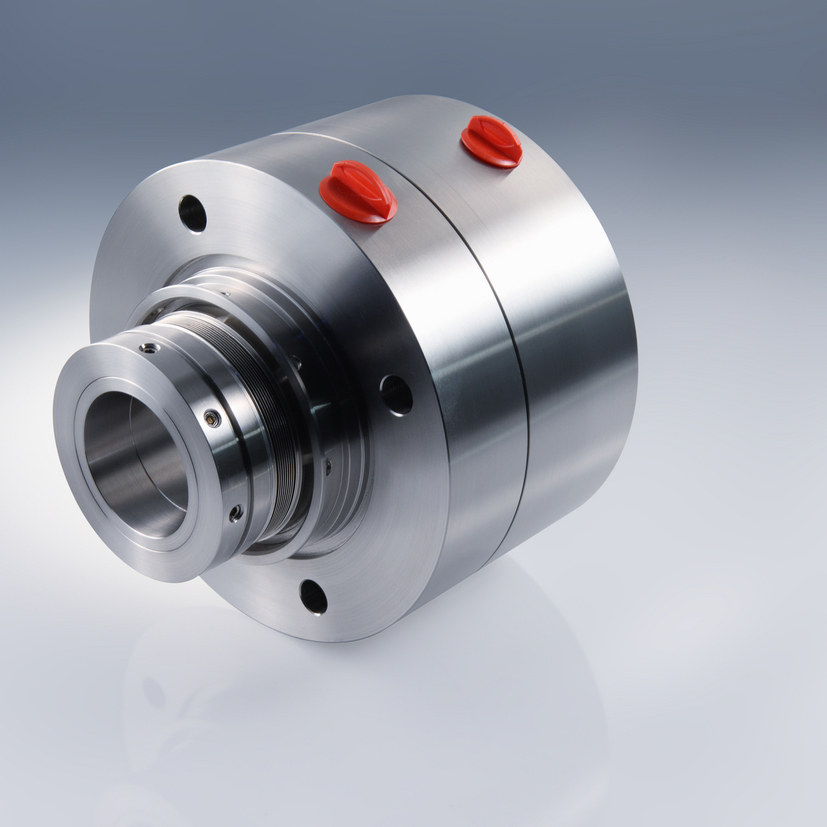

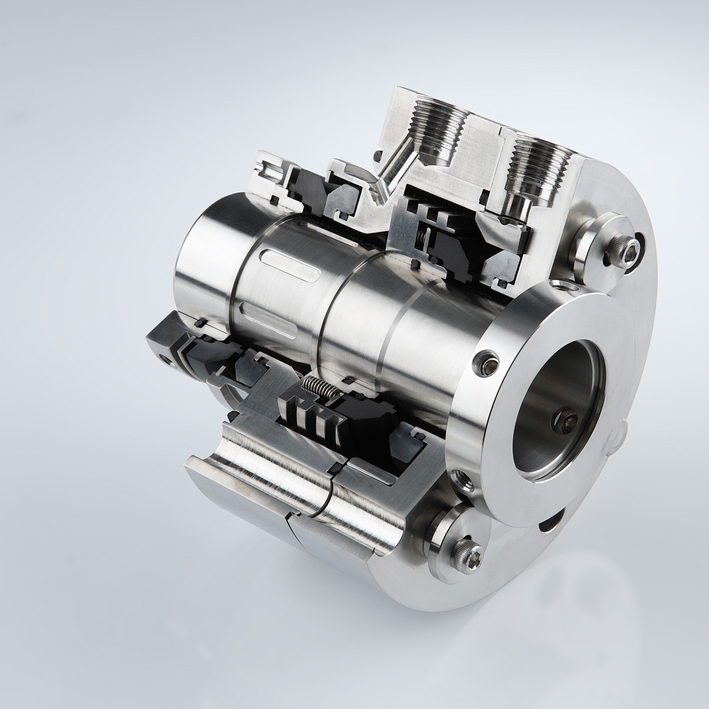

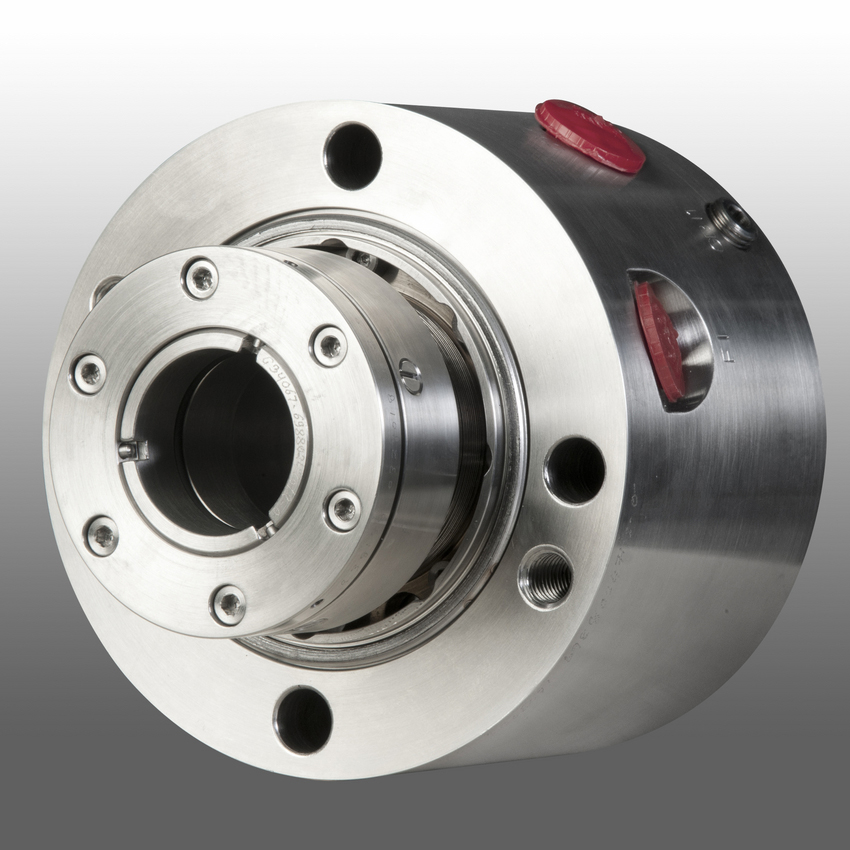

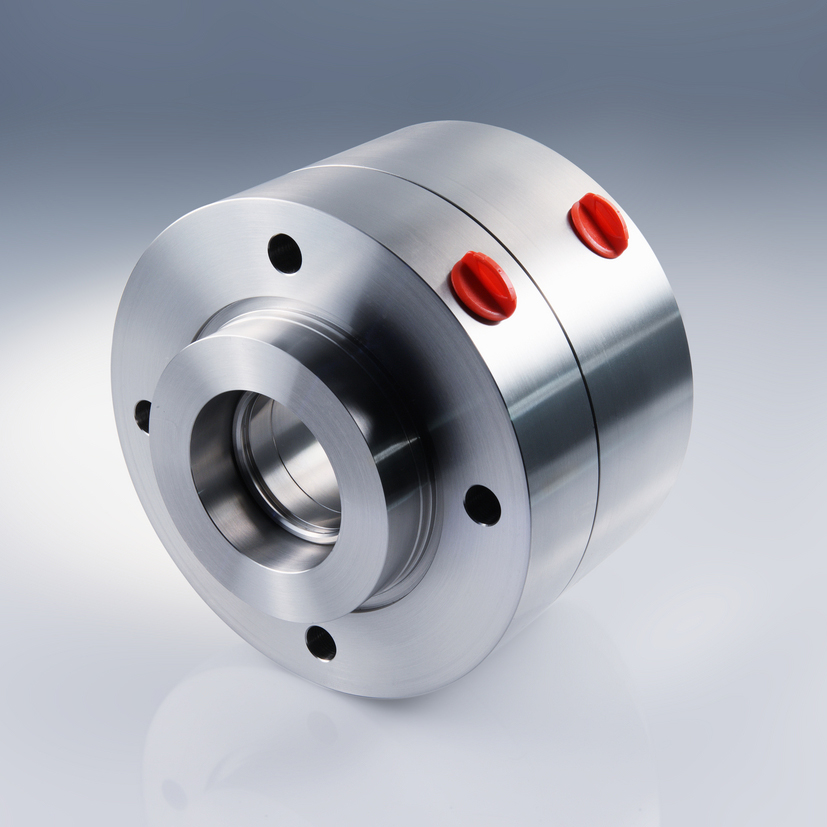

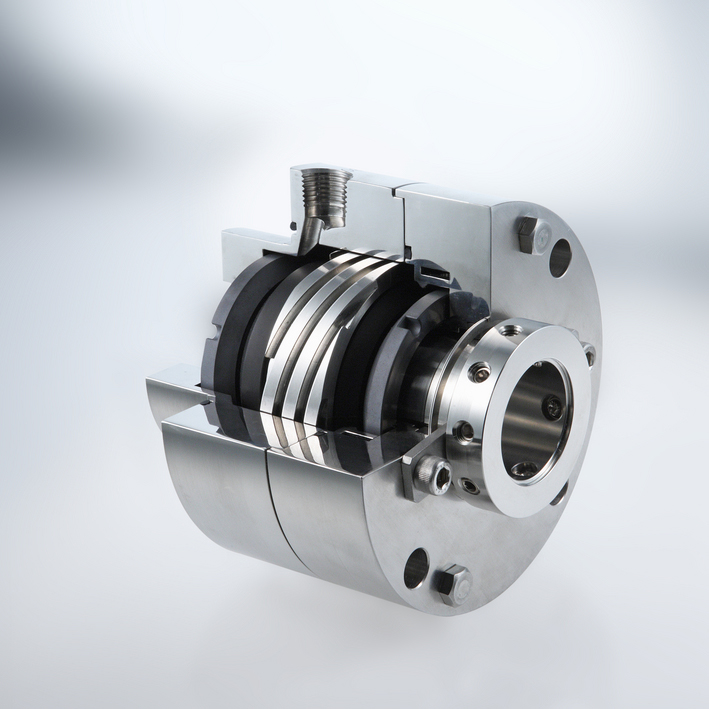

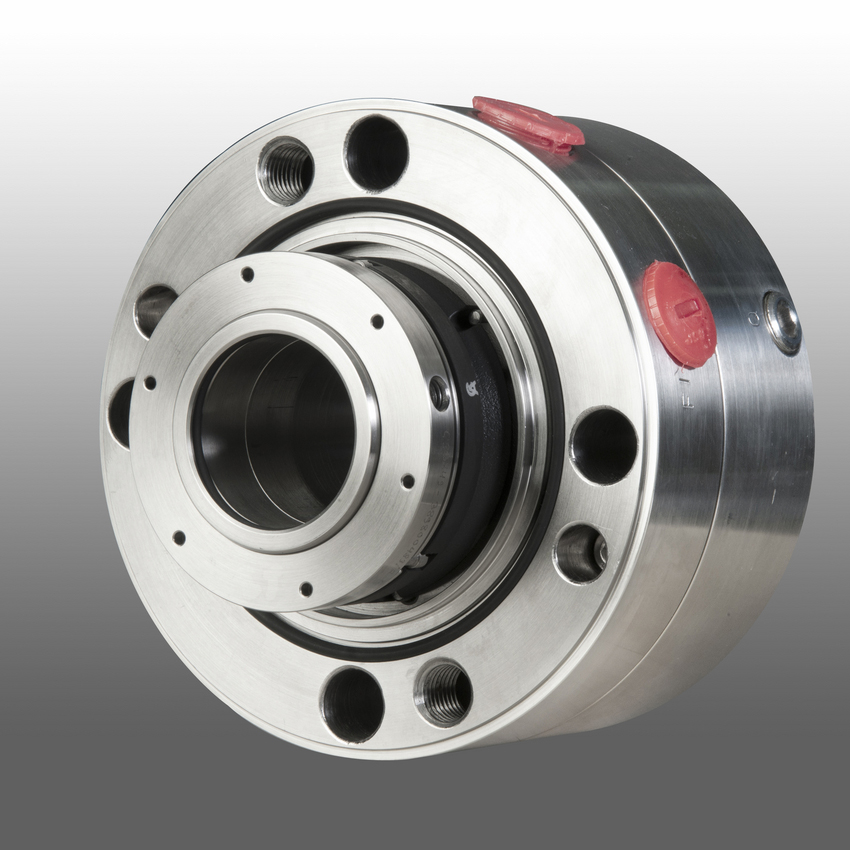

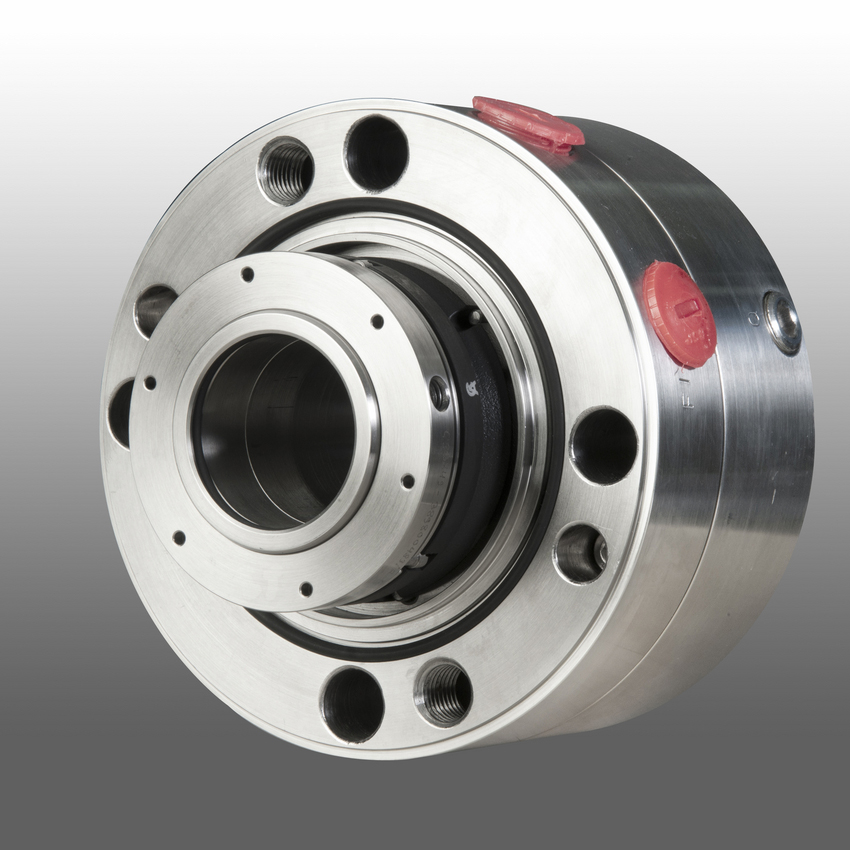

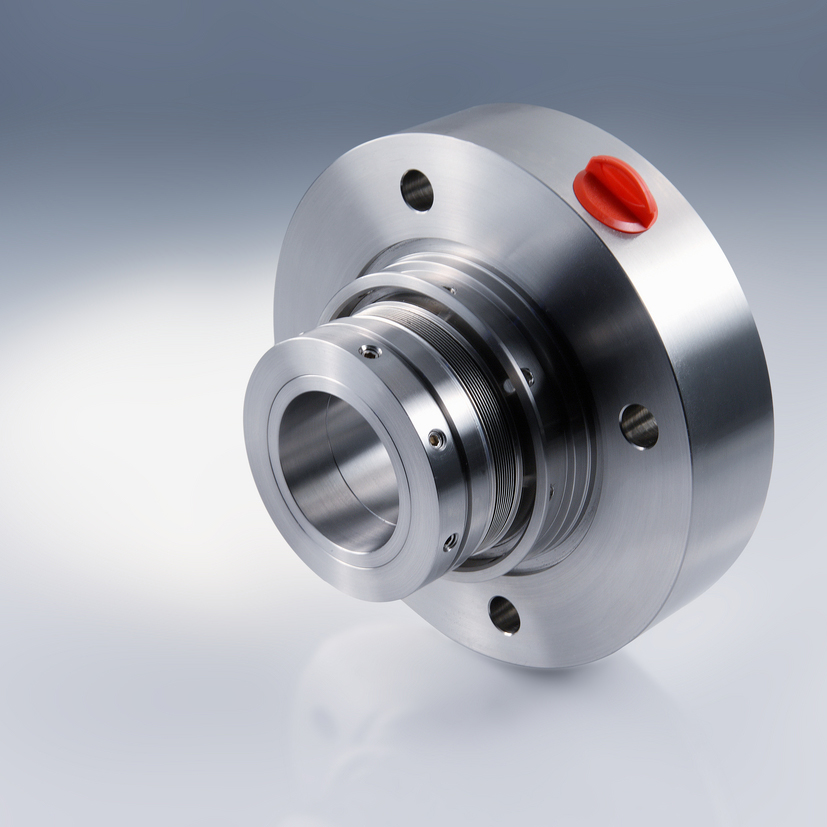

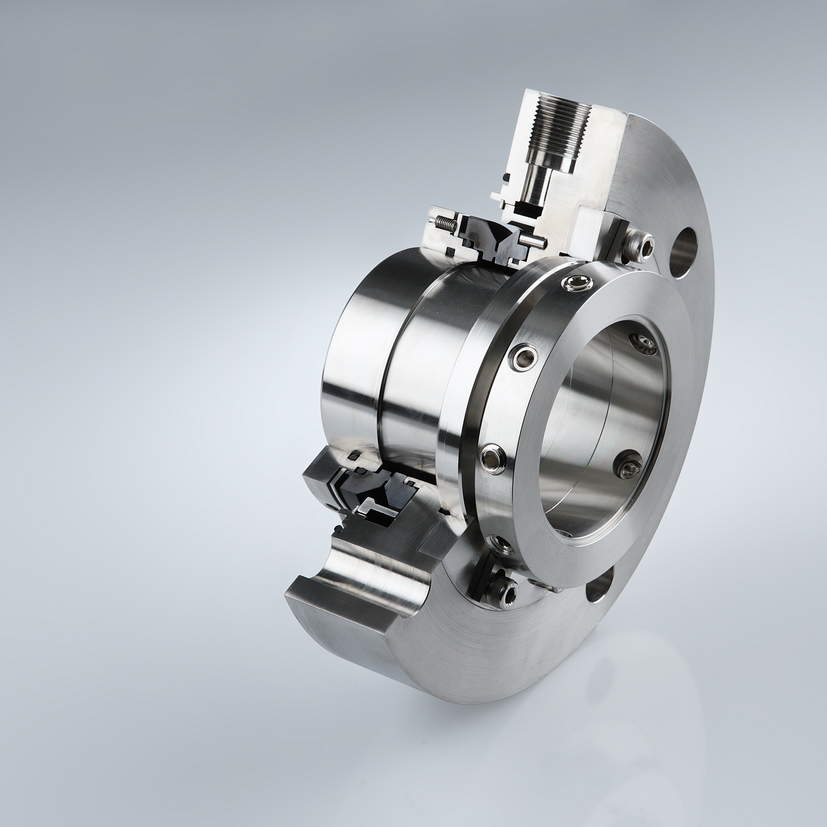

- Mechanical Seals

- Accumulators

- Actuators

- Gas Seals

- Aerospace Seal

- Bearings

- Magnetic Fluid Vacuum Seal

- Segmented Seal

- Stern tube seals

- Tanks

- Coupling, Joint

- Packing, Gasket

- Valves

- Filters

- Brush Seal

- Floating Seal

- Metal bellows, Thin-Walled Metal parts

- Supply Systems

- Hydraulic Regeneration System

- Lip Seal

- Flow meter

- GlideX

-

Search by Industry

-

Search by keyword

-

Sustainability

- Sustainability

- Our concepts of Sustainability

- Participation in Global Initiatives

- Corporate Report

-

Environment

-

Social

-

Governance

-

Investor Relations

- Investor Relations

- Message from the president

- Latest Financial Highlights

- Disclosure Policy

- Disclaimer

-

Stock Information

-

Financial Highlights

-

IR Library

-

Company

Close

This website uses cookies to improve your online experience. By continuing to use this website, we will assume that you are agreeing to our use of cookies. For more information about cookies, please visit our "

Use of cookies" at Privacy Policy.