SUSTAINABILITY

Philosophy

Mechanical seals, the EKK Group’s main product, prevent gases, oil and other fluids used in machinery from leaking out of the machinery. Because such fluid or gas leaks pollute the environment, we believe we help to preserve the environment by providing high-quality/high-performance products.

Environmental issues and regulations specific to our businesses factor into our R&D also. We conduct R&D that not only improves product performance but also yields EKK Group products and technologies that resolve such regulatory issues.

Additionally, we are pursuing various initiatives to minimize the environmental burden even in our production processes.

Environmental Management System

The EKK Group conducts environmental preservation activities in accord with its environmental policy. All subsidiaries in Japan are ISO 14001-certified and participate in an integrated environmental management system.

Compliance with Environmental Laws and Regulations

The EKK Group annually identifies environmental laws and regulations that pertain to its operations and verifies its compliance with them semiannually. No environmental accidents that would constitute a regulatory violation occurred in FY2021. There was one incident that required simple inspections of machinery containing chlorofluorocarbons(CFCs).

The Group has also established emergency response procedures to prevent environmental contamination in the event of an environmental accident or disaster. Its production plants have emergency arrangements in place and periodically check their procedures’ effectiveness by conducting emergency tests.

Environmental Internal Audits and Patrols

All organizational units are internally audited annually. Some 260 employees are certified internal auditors.

Internal auditors undergo a training program before starting to audit. Every fiscal year, they are taught auditingpriorities and other points to check when conducting internal audits. Cross-site internal audits are also conducted to upgrade internal auditors’ skills and increase the audits’ accuracy.

Additionally, environmental patrols are conducted annually at all domestic production sites. Staff from the Safety, Environment & Quality Control Office’s Safety & Environment Management Department visit production sites to inspect frontline operations (management of, e.g., industrial waste, oil and chemicals) and provide guidance.

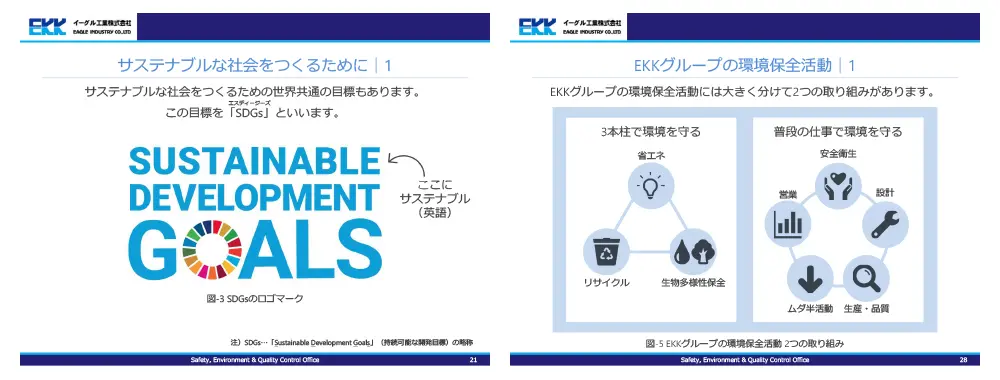

Environmental Education and Consciousness-Raising

All employees receive environmental mindset training annually.The training program uses a uniform curriculum on a Group-wide basis to share the EKK Group’s environmental preservation philosophy and initiatives while also including topical environmental content.

Additionally, environmental performance metrics, including electric power consumption, are disclosed on an intranet portal site to help raise employees’ environmental consciousness.

Initiatives per Theme

Global Warming Mitigation Measures

In order to contribute to the achievement of the Japanese government’s target of reaching carbon neutrality, we are working to develop environmentally friendly products that conserve energy and reduce environmental burden, and adopt renewable energy (solar power) and conserve power in our production processes.

At our production plants, we are improving our energy efficiency by replacing HVAC systems and compressors with more energy-efficient models, switching to LED lighting and sealing compressed air leaks.

Sales branches do so by promoting fuel-efficient driving of Company vehicles and reviewing mileage logs at meetings.

Additionally, all employees are trained to turn off lights when vacating the office, including at lunchtime, and to put computers to sleep when not in use.

In FY2021, we submitted a response to the CDP Climate Change Questionnaire, disclosing our climate change efforts.

Industrial Waste Reduction/Recycling

We are working to achieve a recycling ratio of at least 98% as one of our environmental targets. Some industrial waste that contains substances that preclude recycling is disposed of in landfills. We are analyzing such waste in detail to determine if it can be rendered recyclable. EagleBurgmann Japan Co., Ltd. is now able to recycle abrasive stones used for polishing rubber products.

Preservation of Water Resources

At our plants, we monitor water quality and soil conditions in compliance with environmental laws and regulations.

Our production sites use large quantities of water for cooling equipment and cleaning processes in particular. We are reducing water consumption by recirculating cooling water and converting cleaning processes to solvent-based processes that do not use water.

Preservation of Biodiversity

Production plants’ grounds are periodically inspected for invasive vegetation. If any plants designated as invasive alien species are found on site, they are appropriately eradicated in accord with the Invasive Alien Species Act.

We also endorse the Declaration of Biodiversity and Action Guidelines by the “Keidanren (Japan Business Foundation) Declaration on Biodiversity and Action Guidelines” and will continue to engage in biodiversity-conscious business activities to help realize a sustainable society.