PRODUCTS

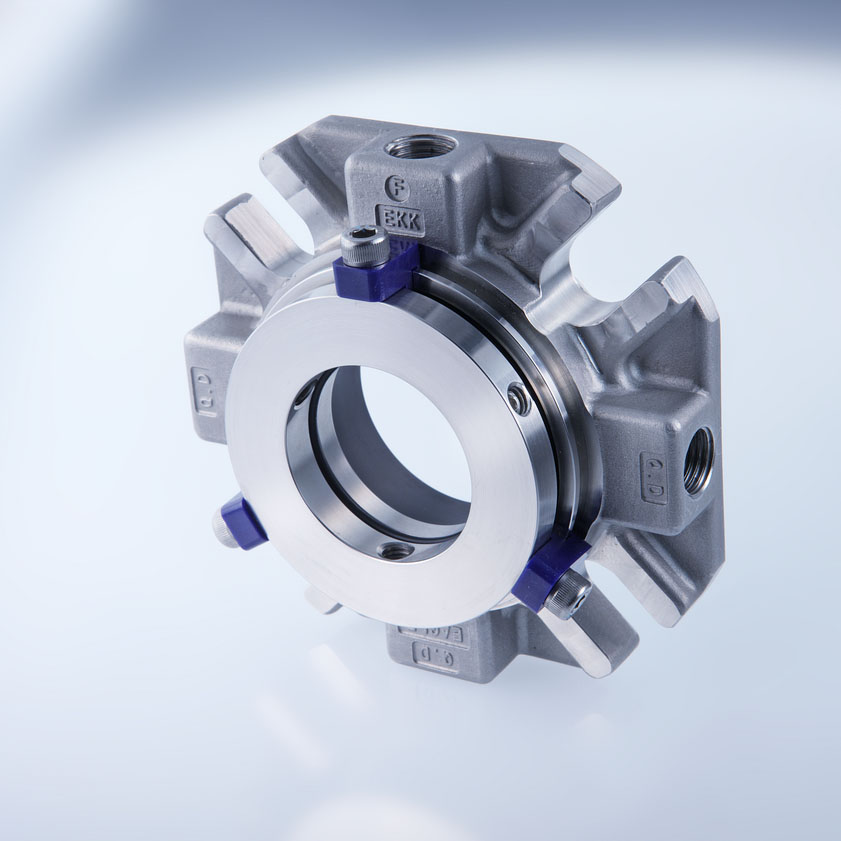

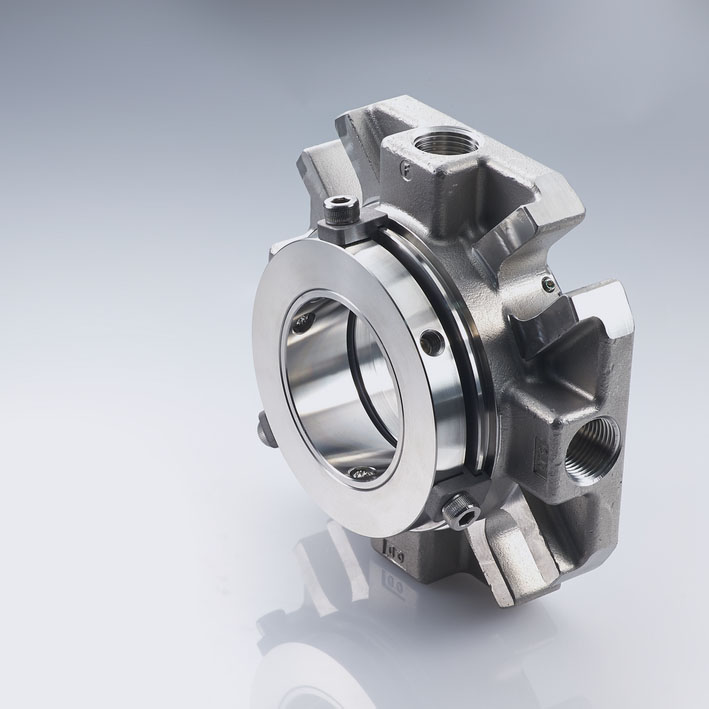

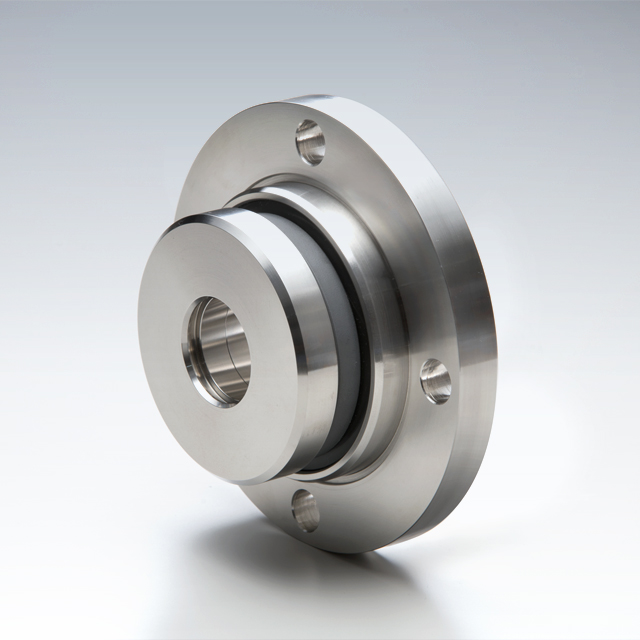

S Series

Slurry Seal

Feature

- Consists of two main parts: O-ring and seal ring. Simple structure minimizing problems and ensuring easy handling

- O-ring serves as the packing; rubber elasticity used to provide a spring force; rubber friction ensures anti-rotation

- Special nitrile rubber characterized by minimal permanent strain used as the standard O-ring material

- Shrink-fit structure employed for the seal ring. Standard materials: highly corrosion resistant stainless steel for the metal parts, and hard metal alloy (characterized by superb corrosion resistance and wear resistance) for the sliding material

- Titanium/Silicon carbide structure for special conditions

- Can be adopted under positive pressure or under back pressure

Product specification example

Operating range

Pressure: 3 bar (44 PSI) for the seal main unit, 2 bar (29 PSI) including the case

Temperature: 70 ºC (150 ⁰F)

Sliding velocity: 6 m/s (20 ft/s)

Seal liquids

Sealing the movable part in (1) sewerage/food pumps and equipment and (2) large vertical pumps; sealing vertical pump bearings; sealing slurry liquid/single-shaft pumps, etc.

Main applications

- Large pumps for irrigation

- Pumps for ocean civil engineering

- Process pumps for coal liquefaction

- Slurry pumps

Applicable ranges, performance data and figures can serve only as a guide for selection and therefore in actual use there will be some cases where general specifications cannot be applied due to unknown factors or constraints.

Please check the applicability before use.

The contents are subject to change without notice for improvement.