PRODUCTS

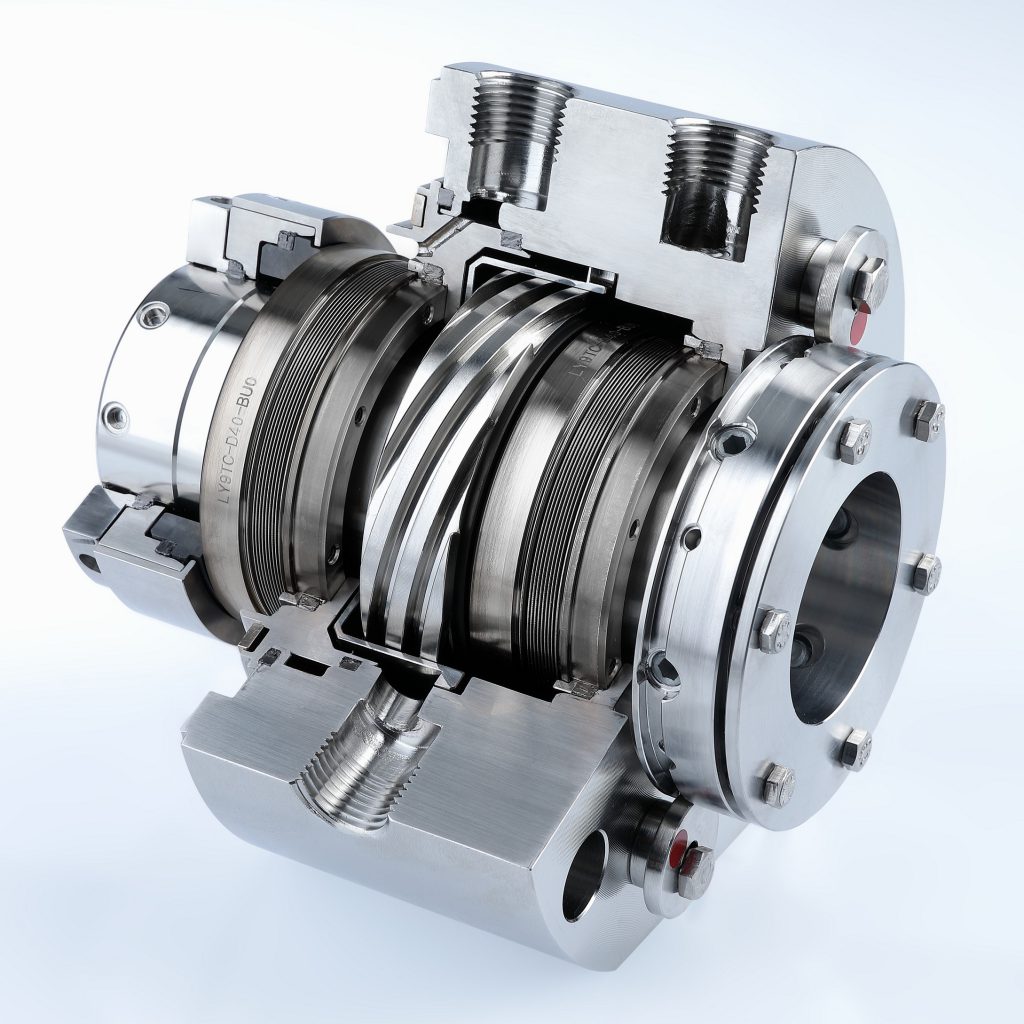

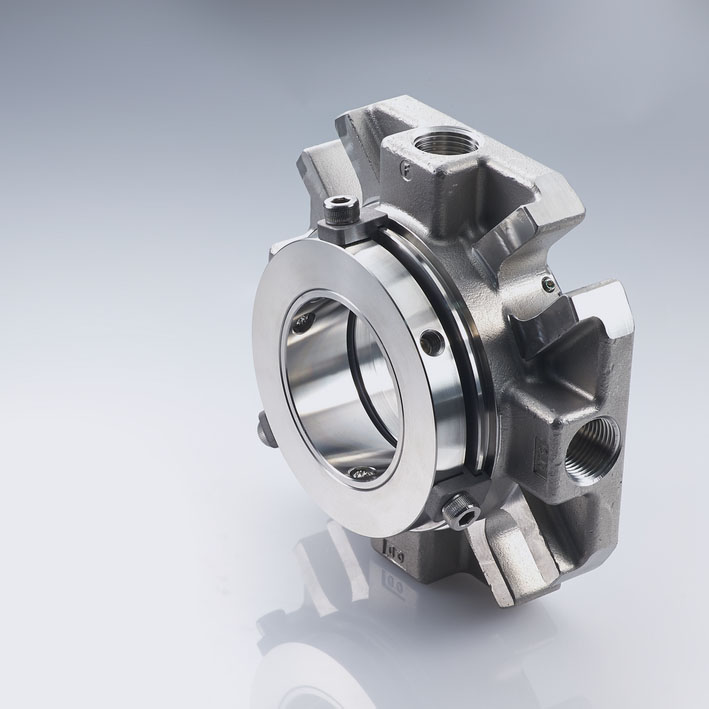

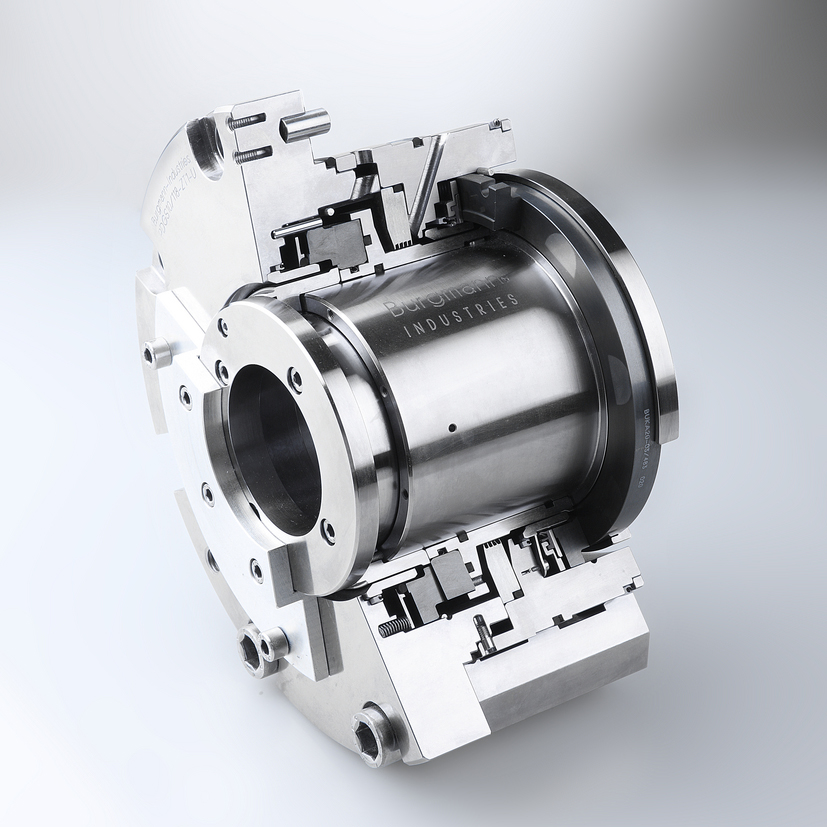

LY9TCS

API Standard 682 seal

Feature

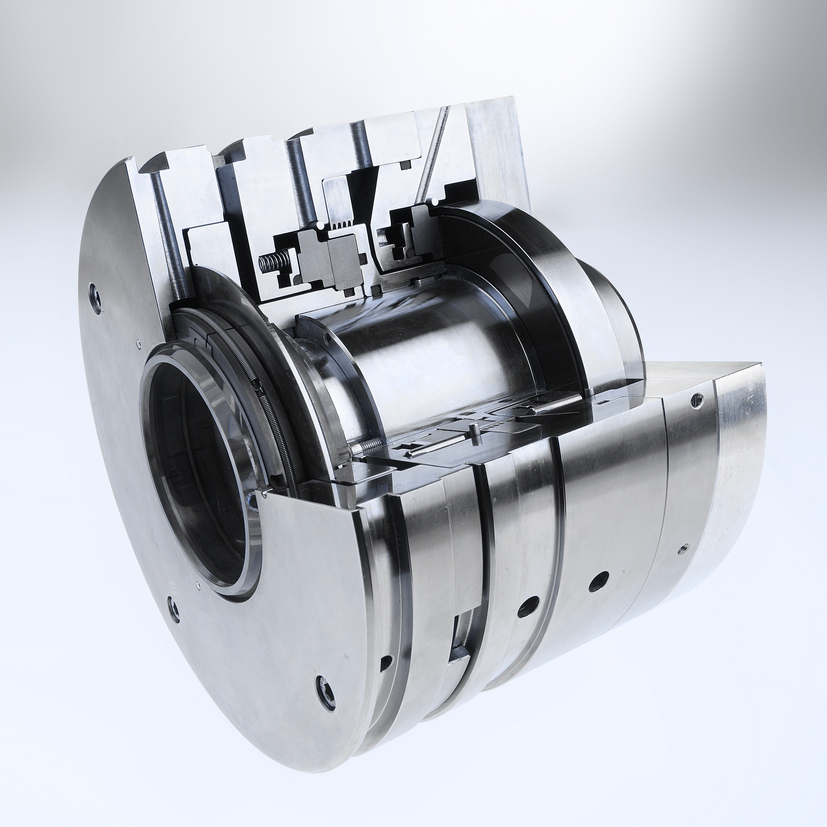

- API 682 Category 2&3, Type C, Arrangement 1/2/3 seal

- Balanced

- Cartridge unit

- Rotating metal bellows single/tandem/dual seal

- Shrink fitted seal ring and solid mating ring

Product specification example

Standards and approvals

API 682 / ISO 21049

Materials

Seal ring: Blister resistant carbon,

Silicon carbide SSiC (Q1), RBSiC (Q2)

Mating ring:

Silicon carbide SSiC (Q1), RBSiC (Q2)

Bellows: Inconel® 718 (M6)

Secondary seals: Graphite (G)

Metal parts: CrNiMo steel 316 (G), Carpenter® 42 (T4)

Operating range

Pressure single ply bellows: p = vacuum … 25 bar (… 363 PSI)*

Pressure double ply bellows: p = vacuum … 35 bar (… 508 PSI)

Temperature: t = -75 ºC … +400 ºC

(-103 ºF … +752 ºF)

Sliding velocity: vg … 50 m/s (… 164 ft/s)

Viscosity: … 1,000 mPas

Solids content: … 0.5 wt.%

* p >20 bar (290 PSI) on request.

Recommended applications

Refining technology

Oil and gas industry

Petrochemical industry

Chemical industry

Power plant technology

LPG plants

API 610 / ISO 13709 pumps

Process pumps

Recommended piping plans

Process side:

01, 02, 03, 11, 12, 13, 14, 21, 22, 23, 31, 32, 41

Between seals:

52, 53A, 53B, 53C, 54, 55

Atmospheric side*:

51, 61, 62, 65A, 65B, 66A, 66B

* Throttle bushing for tandem/dual seal on request

Applicable ranges, performance data and figures can serve only as a guide for selection and therefore in actual use there will be some cases where general specifications cannot be applied due to unknown factors or constraints.

Please check the applicability before use.

The contents are subject to change without notice for improvement.

Download Documentation