PRODUCTS

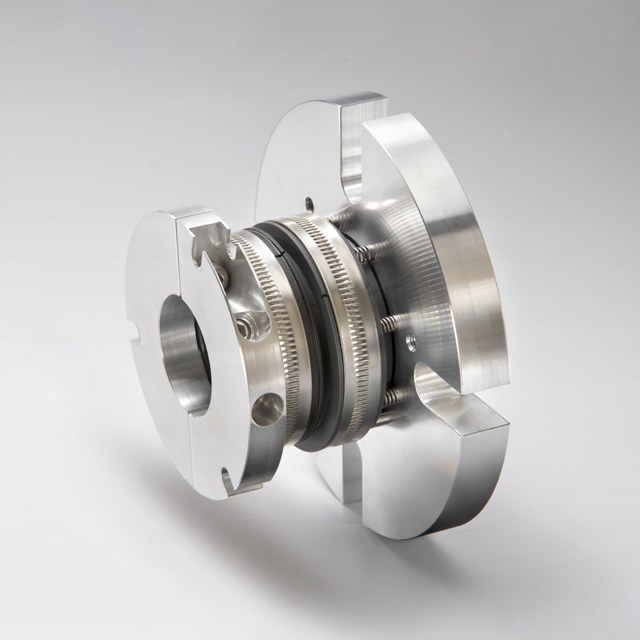

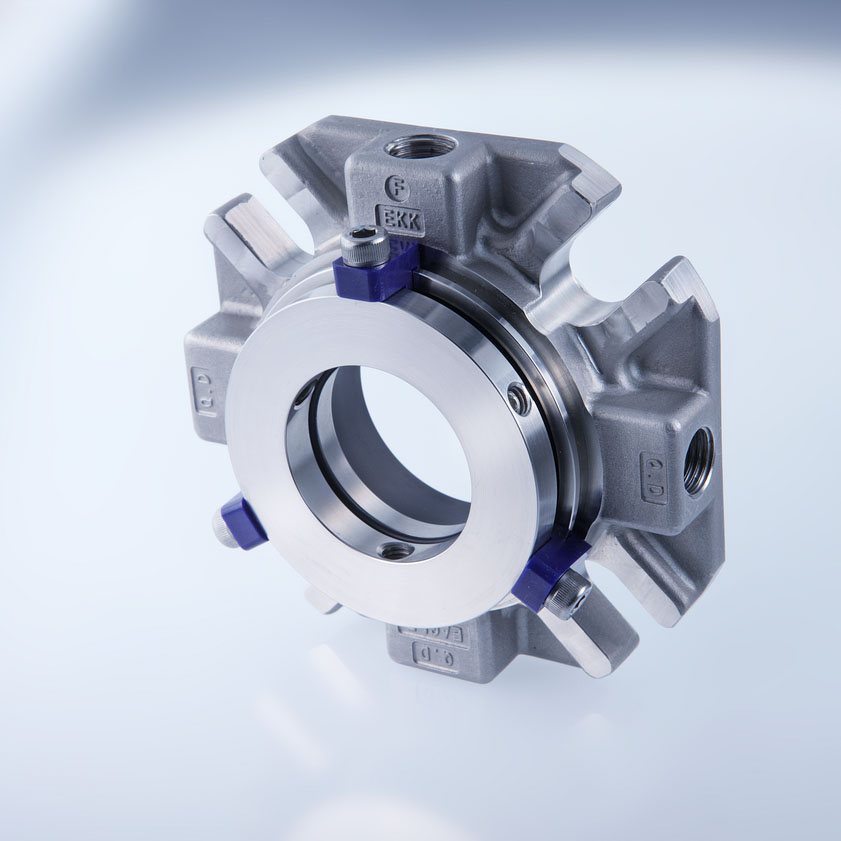

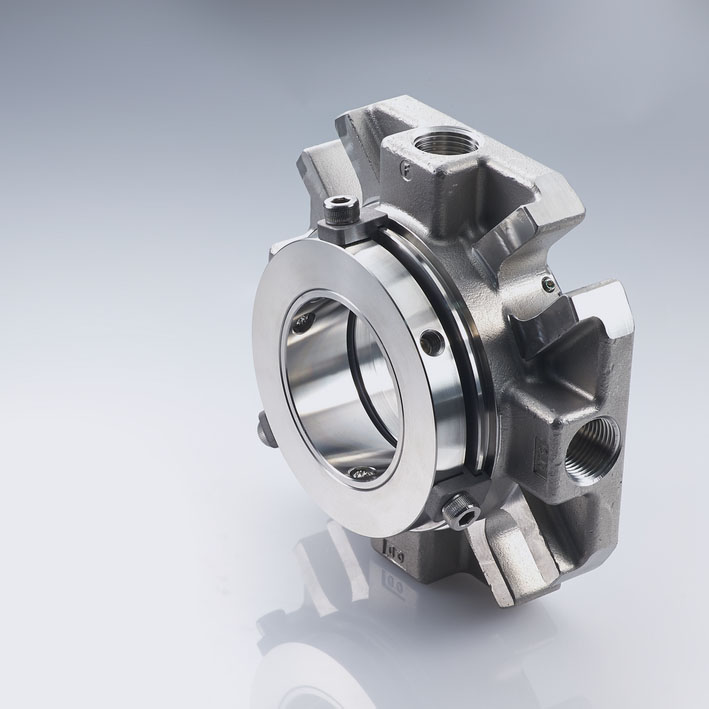

C Series

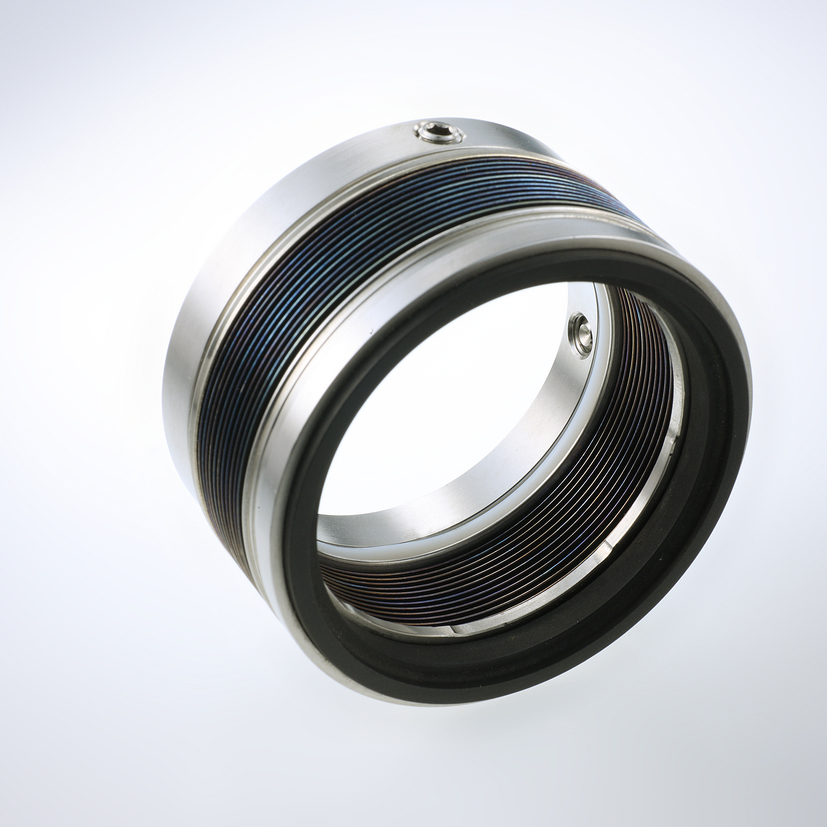

Cut Seal

Feature

High performance

- A stationary type with good followability

- Designed to minimize any sludge clogging in respective parts

- Structure that prevents the spring and pin from contacting the sludge

- Outside type ensures superb heat radiation

Long life

- Uses silicon carbide that is highly resistant to sludge

- Avoids decrease in performance due to sludge

- Designed to minimize the damage and wear on the sliding surface

- Capable of ensuring air-cooling by the atmosphere-side rotating element

Superb installability

- Pre-assembled cartridge seal ensures installation with an accurate setting length

- An ultra-thin seal installable in small spaces

Minimal maintenance

- Extends the replacement intervals, and reduces the number of operations required

- Significantly reduces the time and labor required for assembly/disassembly

Cost-saving, no equipment cost required

- No flow relays, piping, or valves required

Product specification example

Materials

Seal face: Silicon carbide

Seat: Silicon carbide

Metal parts: CrNiMo steel 316 (G)

Secondary seals: FKM (V)

Operating range

Pressure: 5 bar (73 PSI)

Sliding velocity: 15 m/s (49 ft/s)

Temperature: 0 ºC to 80 ºC (32 ⁰F to 176 ⁰F)

Viscosity: 1 Pa・s

Solids content: 10 wt%

Main applications

- Purification center: sewage pumps, sludge pumps

- Ironworks: coolant pumps, water circulation pumps

- Power plants: water supply pumps, drainage pumps, coolant pumps, etc.

Applicable ranges, performance data and figures can serve only as a guide for selection and therefore in actual use there will be some cases where general specifications cannot be applied due to unknown factors or constraints.

Please check the applicability before use.

The contents are subject to change without notice for improvement.