PRODUCTS

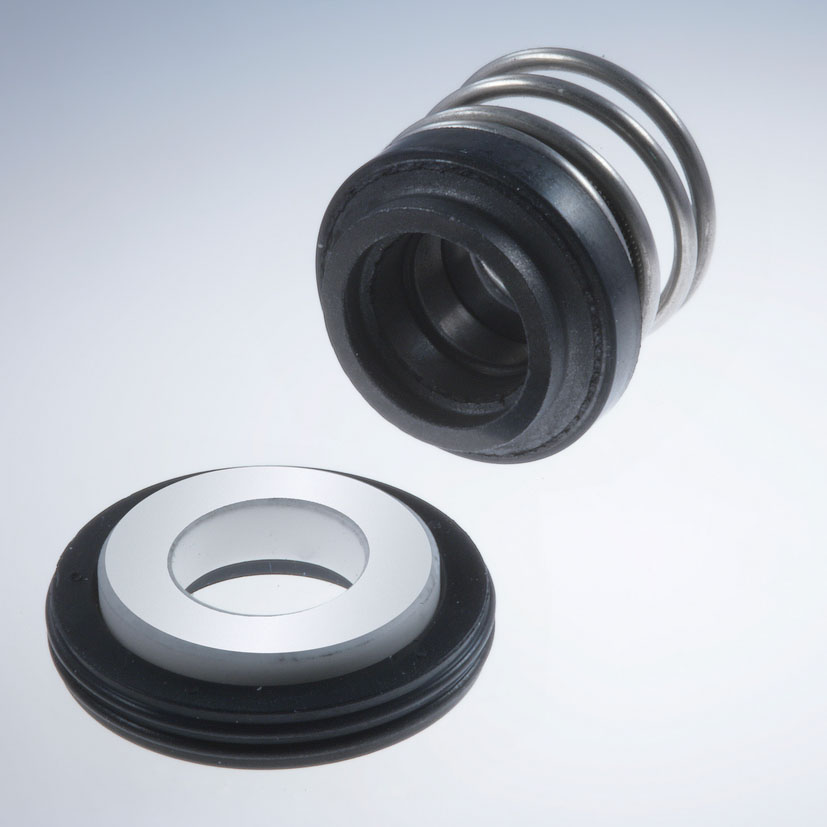

EA100

Versatile Mechanical Seal

Feature

- Single seal

- In-house manufactured carbon seal faces

- Three different impeller connections available

Product specification example

Materials

Seal face: Carbon graphite resin

impregnated (B)

Seat: Aluminium oxide (V)

Elastomer: NBR (P)

Metal parts: CrNi steel (F)

Operating range

Shaft diameter: d1 = 8 … 20 mm (0.32″ … 0.78″)

Pressure: p1 = 5 bar (73 PSI), vacuum up to 0.1 bar (1.45 PSI)

Temperature: t = -20 °C … +80 °C (-4 °F… +176 °F)

Sliding velocity: vg = 5 m/s (16 ft/s)

Solids content:0.05wt.%

Recommended applications

Water and waste water technology

Drinking water

Hot water circulation pumps

Industrial pumps/equipment

Domestic pumps

Low duty water pumps

Pumps for water & under floor

Heating systems

Pumps for solar systems

Product variants

EA102

As EA100 but with a collar.

EA103

As EA100 but without a collar. Please inquire.

EA104

As EA100 but with different coil spring installations. Please inquire.

This product is a mass production model and therefore it is not suitable for nuclear or aerospace applications as they require individual controls.

Applicable ranges, performance data and figures can serve only as a guide for selection and therefore in actual use there will be some cases where general specifications cannot be applied due to unknown factors or constraints.

Please check the applicability before use.

The contents are subject to change without notice for improvement.

Download Documentation