PRODUCTS

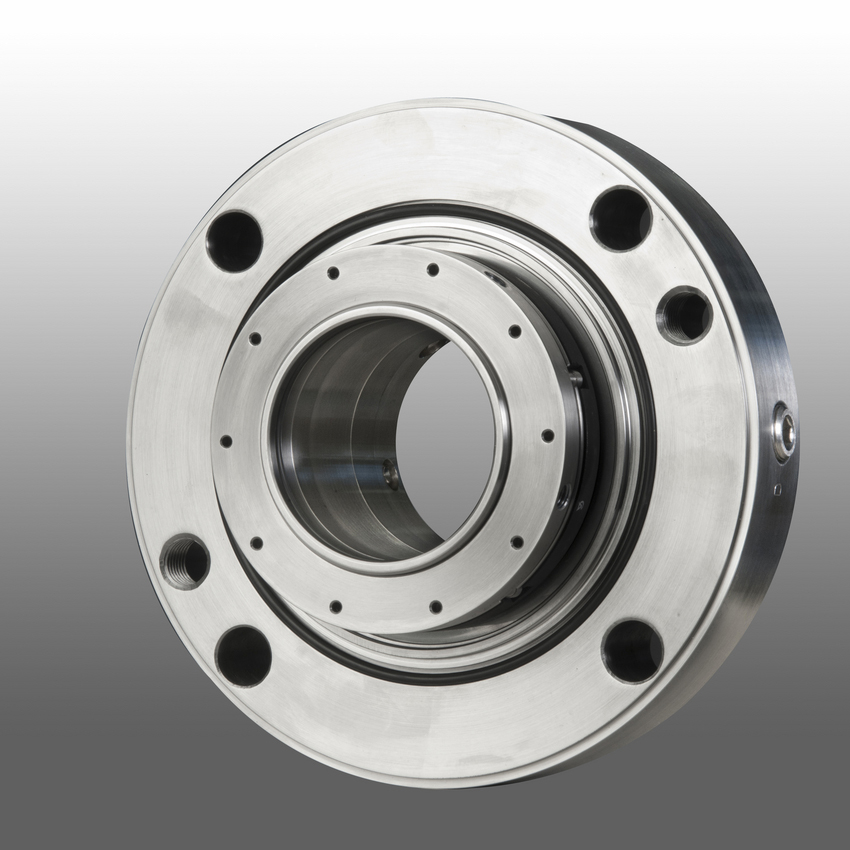

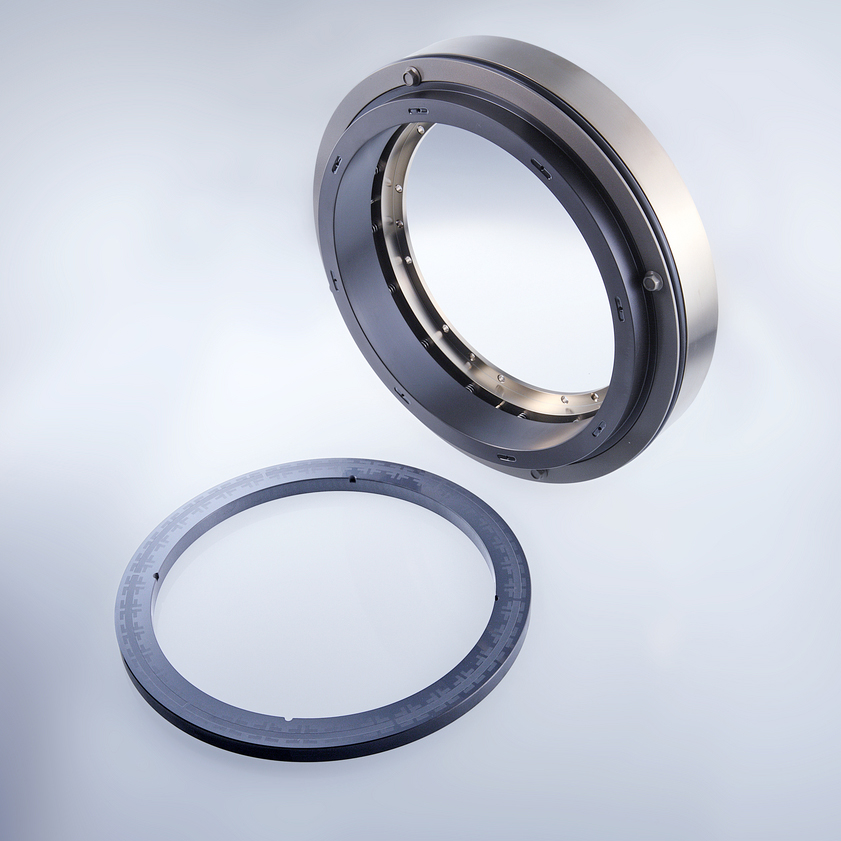

Diaphragm Coupling

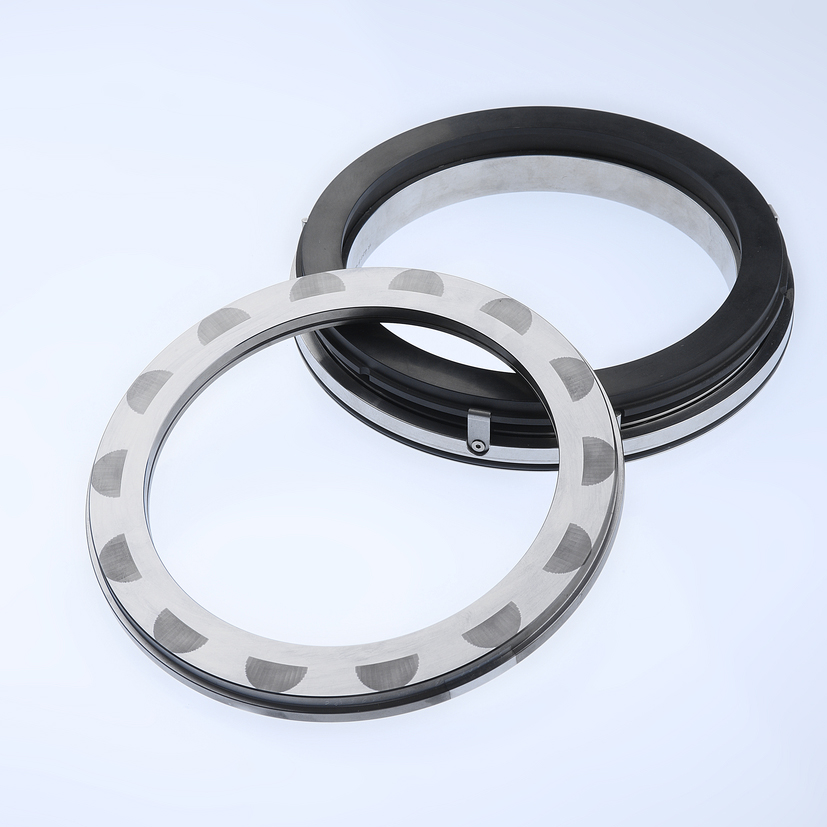

Feature

- Special diaphragm shape enables to transmit a large torque, low load on the bearing

- Simple structure ensures easy installation/removal, lightweight

- Optimum for high speeds (100,000 rpm max.)

- Having no movable/frictional parts, this coupling does not require lubrication nor have noise, vibration, backlash, change in dynamic balance.

Product specification example

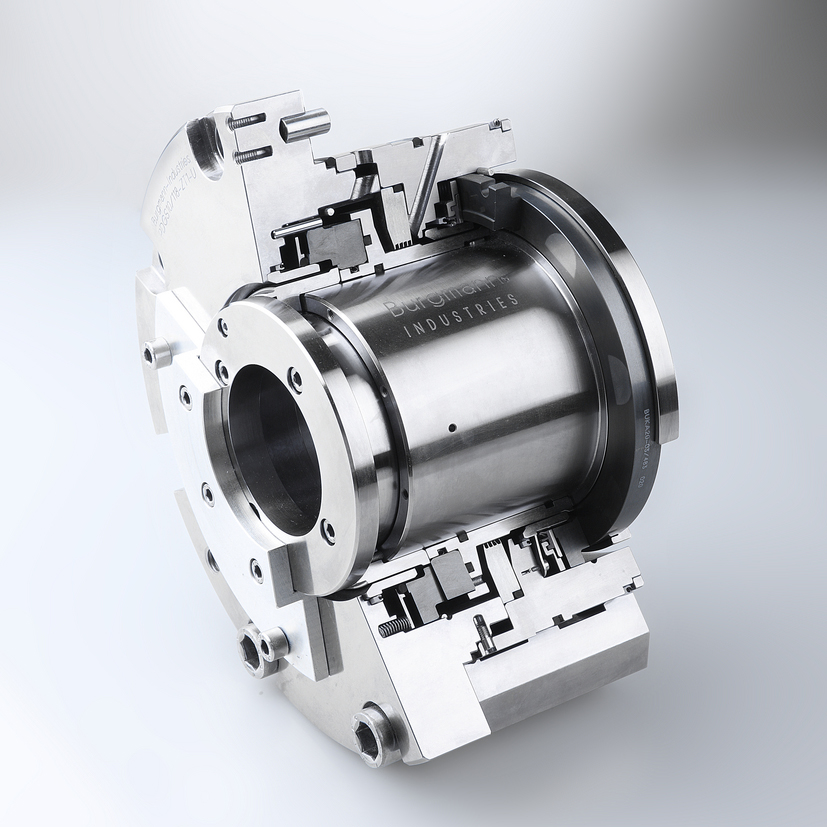

Model 66

- Special low alloy steel used for the diaphragm

- Main applications: general-purpose pumps, precision machine tools, general-purpose machines, main engines/auxiliary equipment for vessels, power generator

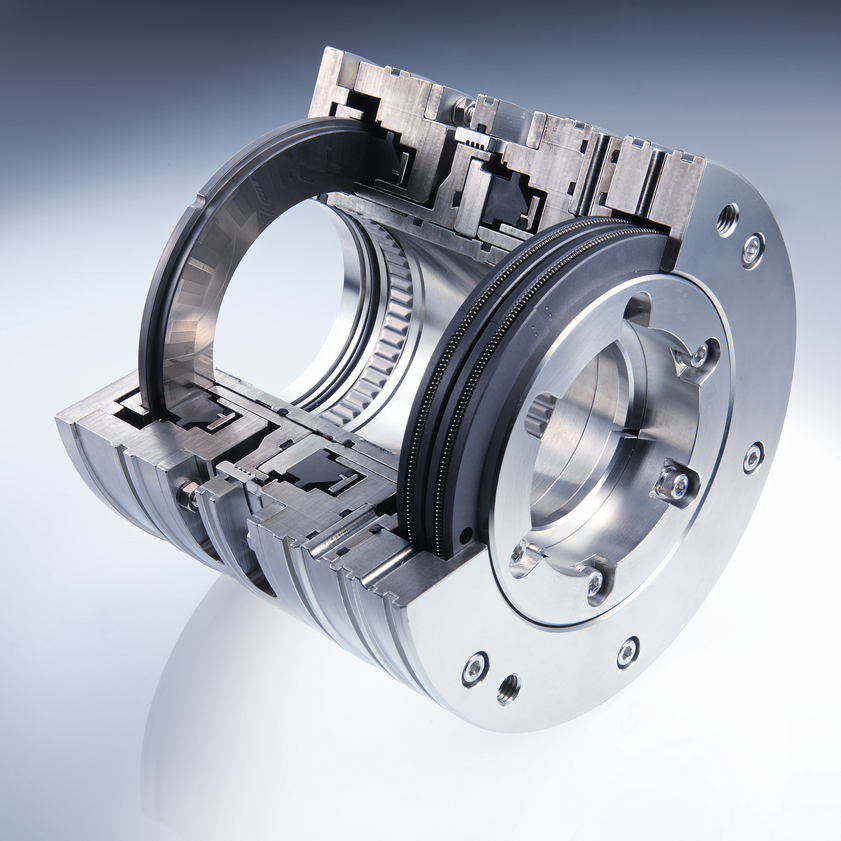

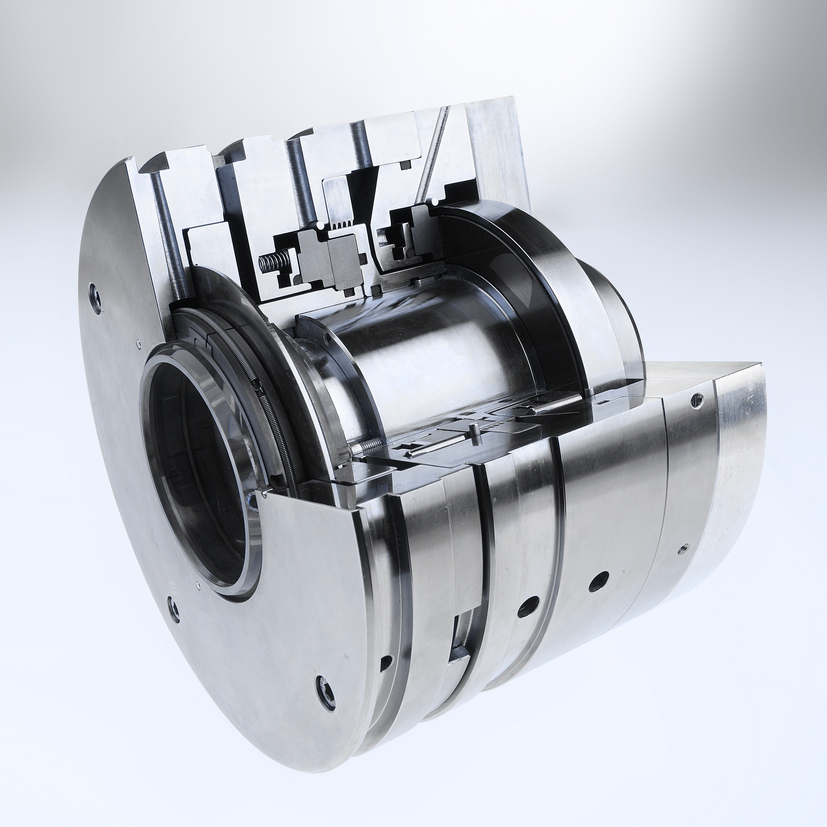

Model 67/74 Model 99/100 Complies with API 671, high-speed/high-torque specifications

- Model 67/99: Complies with low-speed specifications of the API 671 standard

- Model 74/100: Complies with mid-/high-speed specifications of the API 671 standards

- Model 67/74: special low alloy steel used for the diaphragm

- Model 99/100: special pre cipitation-hardening stainless steel used for the diaphragm

- Main applications: gas/steam turbine driving systems, compressors, large combined power generation system

Applicable ranges shown in the product introduction are limit values for each standard material.

Applicable ranges, performance data and figures can serve only as a guide for selection and therefore in actual use there will be some cases where general specifications cannot be applied due to unknown factors or constraints.

Please check the applicability before use.

The contents are subject to change without notice for improvement.

Applicable ranges, performance data and figures can serve only as a guide for selection and therefore in actual use there will be some cases where general specifications cannot be applied due to unknown factors or constraints.

Please check the applicability before use.

The contents are subject to change without notice for improvement.

Download Documentation