PRODUCTS

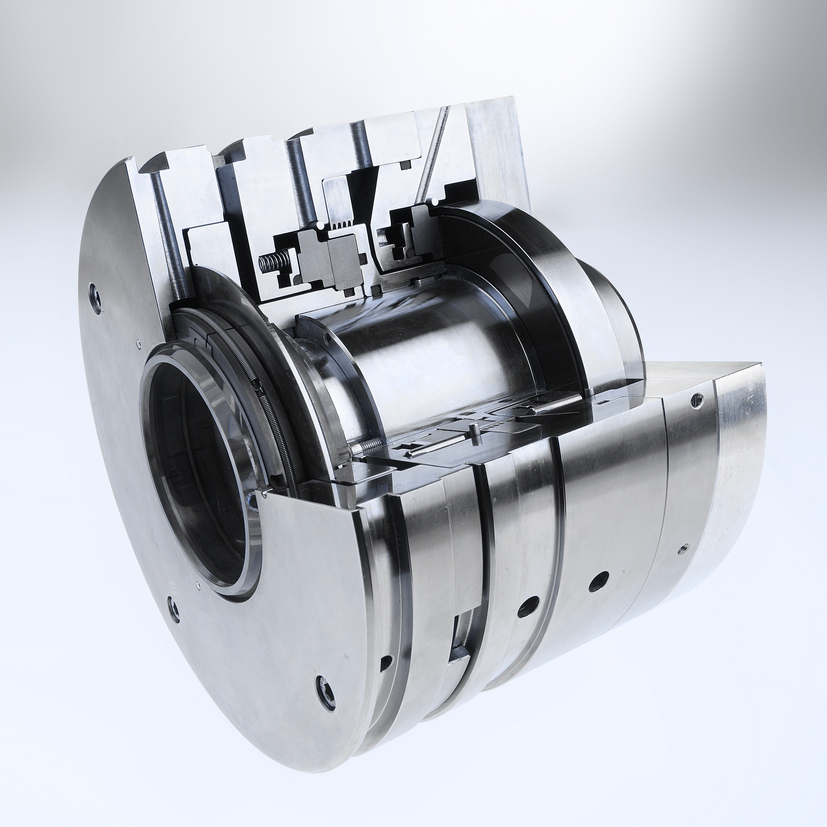

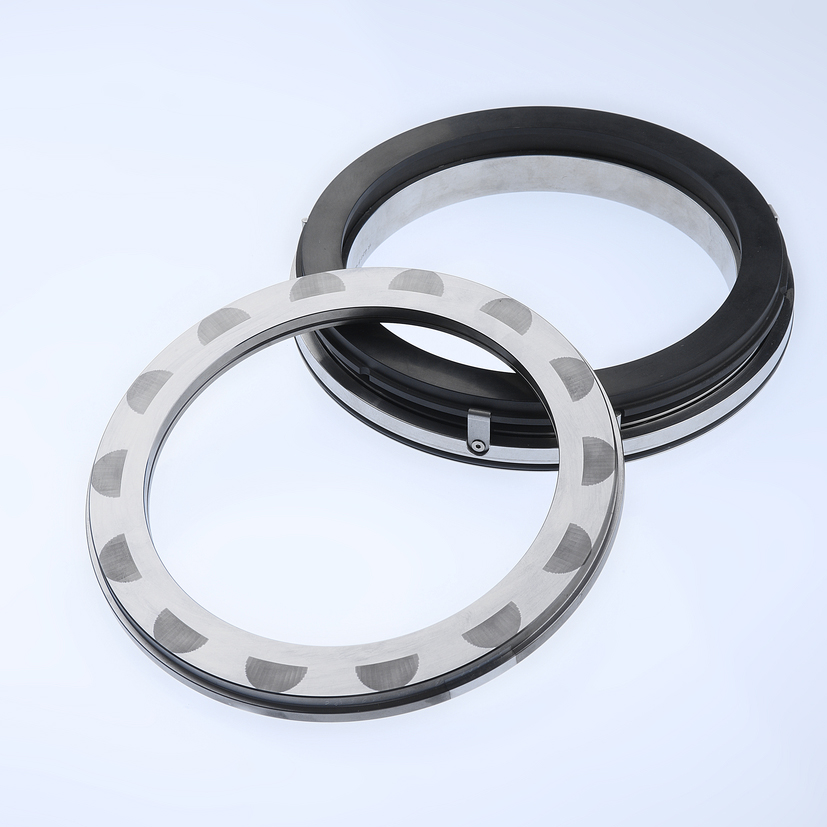

DGS

Gas-Lubricated Seal

Feature

- Gas-lubricated

- Unidirectional or bidirectional available

- Ready-to-fit cartridge unit

- Single, Dual, Tandem and Tandem with intermediate labyrinth available

Product specification example

Standards and approvals

NACE

Materials

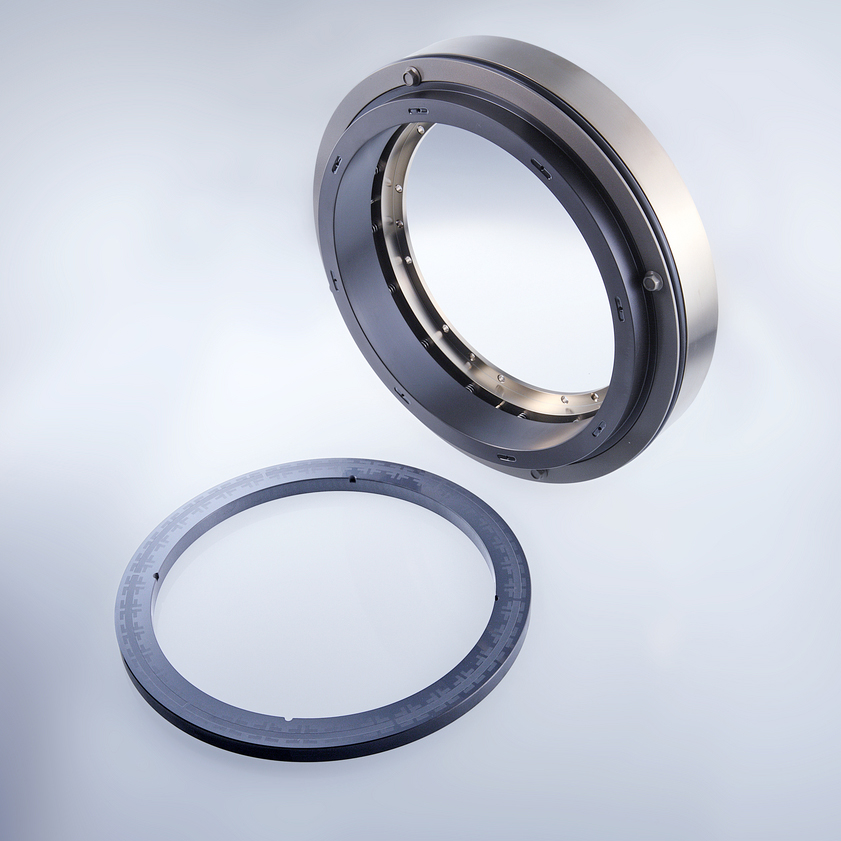

Seal face: Silicon carbide (Q1) with DLC coating

Seat: Silicon carbide (Q1) with DLC coating

Secondary seals: FKM (V)*

Metal parts: 1.4006 (SS410) or other stainless steels

* Or other materials depending on product gas composition.

Operating range

Pressure: p = 0 … 100 bar (1,450 PSI)

Temperature: t = -20 °C … 200 °C (-4 °F … 392 °F)

Sliding velocitiy: vg = 0.6 … 200 m/s (2 … 656 ft/s)

Recommended applications

Oil and gas industry

Refining technology

Petrochemical industry

Hydrocarbon gas

Ammonia

Nitrogen

Air

Centrifugal compressors

Turbo expanders

Blowers

Installation, Details, Options

Separation seals as labyrinths, contacting (CSE), non-contacting (CSR) or aerostatic (CobaSeal) bushing seals are optionally available.

Product variants

DGS Tandem seal

Application: Where small product leakages of process gas are admissible, e.g. on gas pipeline compressors. Seal on the atmosphere side acting as a safety seal.

The tandem arrangement provides a particularly high degree of operational safety. The seal on the product side and the seal on the atmosphere side are able to absorb the complete pressure. Under normal operating

conditions the full pressure is reduced only by the seal on the product side. The space between the seal on the product side and the seal on the atmosphere side is cleared by a connection “B” to the primary vent (flare).

The pressure to be sealed by the seal on the atmosphere side equals the primary vent pressure, so the leakage to the secondary vent (atmosphere) is very low. If the main seal fails, the second seal acts as a safety seal.

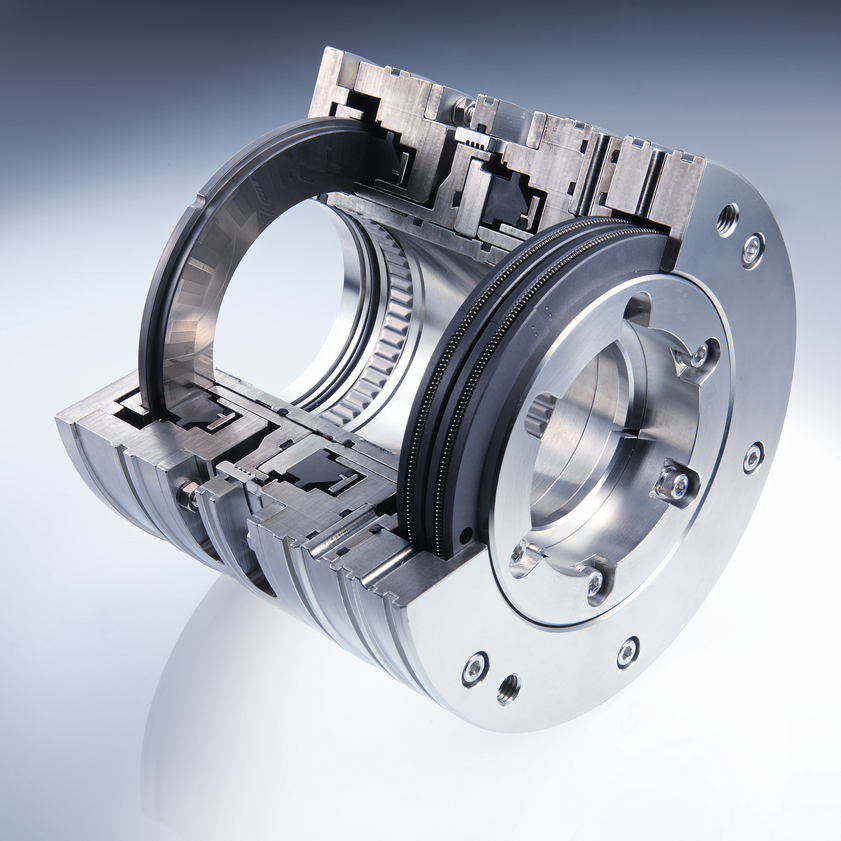

DGS Tandem seal with intermedia labyrinth

Application: Where product leakages to the atmosphere as well as nitrogen leakages (from a

dual seal) to the product are inadmissible, e.g. on H2, ethylene or propylene compressors. With this arrangement the pressure to be sealed is reduced via the primary seal on the product side and the entire process gas leakage is discharged via connection “B” to the primary vent. This is ensured by supplying the atmospheric side seal with secondary seal gas (nitrogen) via connection “C”. The pressure of the secondary seal gas ensures that nitrogen flows via the

labyrinth to the primary vent connection “B” together with the complete process gas leakage.

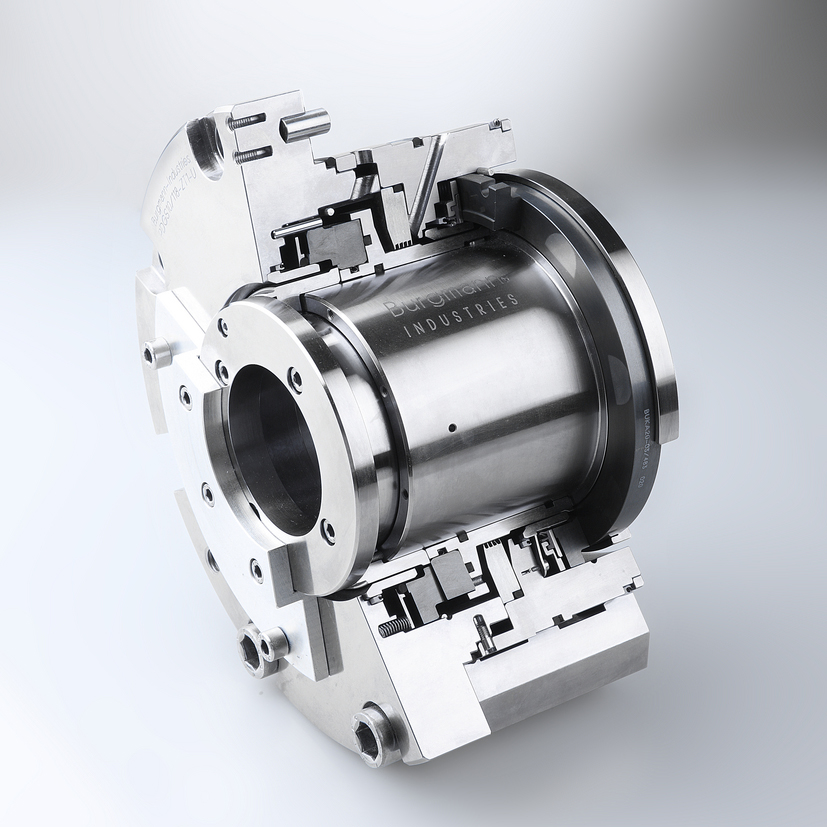

DGS Dual Seal

Application: Where product leakages to the tmosphere are inadmissible and tandem arrangements are not suitable because of too small product gas pressures. Buffer gas leakages into the product must be admissible (buffer pressure p3 > p1). This seal is used when a neutral buffer gas of suitable pressure is available. Typical applications are to be found mainly in the chemical industry, e.g. on HC gas compressors. A buffer gas, e.g. nitrogen, is fed between the seals via connection “C” at a higher pressure than the product pressure. One part of the buffer gas leakage escapes to the atmosphere side and the other part to the product.

Applicable ranges, performance data and figures can serve only as a guide for selection and therefore in actual use there will be some cases where general specifications cannot be applied due to unknown factors or constraints.

Please check the applicability before use.

The contents are subject to change without notice for improvement.

Download Documentation