ABOUT US

Surface Textured Mechanical Seal

- World’s first sealing technology that achieves extra-low friction and high sealing performance

- What is a Textured Surface?

- Seal Characteristics by Application

- Application examples of surface texturing technology

- Award History

- Published Papers and Bibliography

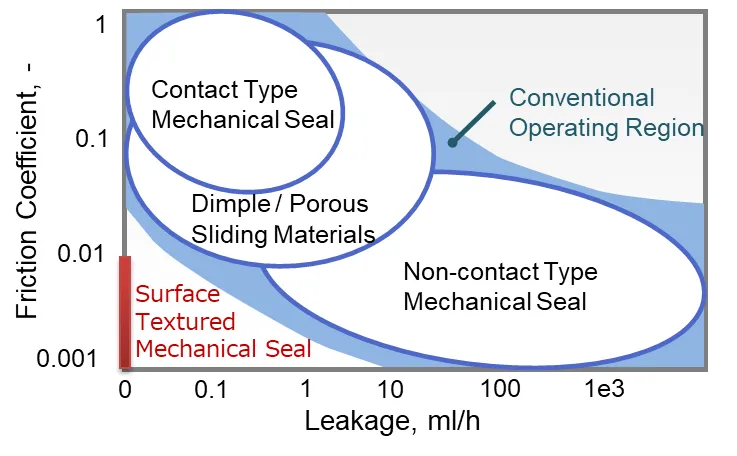

World’s first sealing technology that achieves extra-low friction and high sealing performance

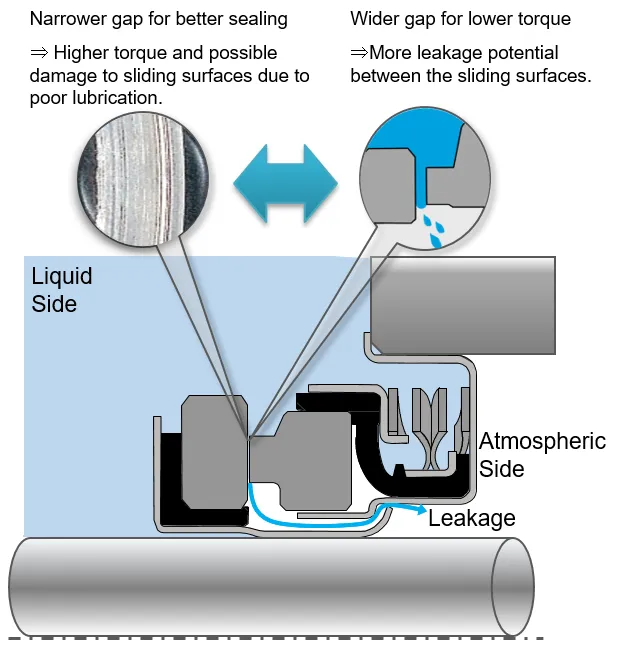

The most important function of a mechanical seal is fluid containment: to prevent leakage. By design, fluid film is created between sliding surfaces to reduce friction and dynamic torque, but the resulting gap increases potential for leakage. In contrast, narrower gap reduces leakage while torque increases.

Therefore, it had not been feasible to offer a mechanical seal with both low torque and superior sealing capabilities.

With introduction of surface texturing technology, EKK is the first to bring these two contraries together.

What is a Textured Surface?

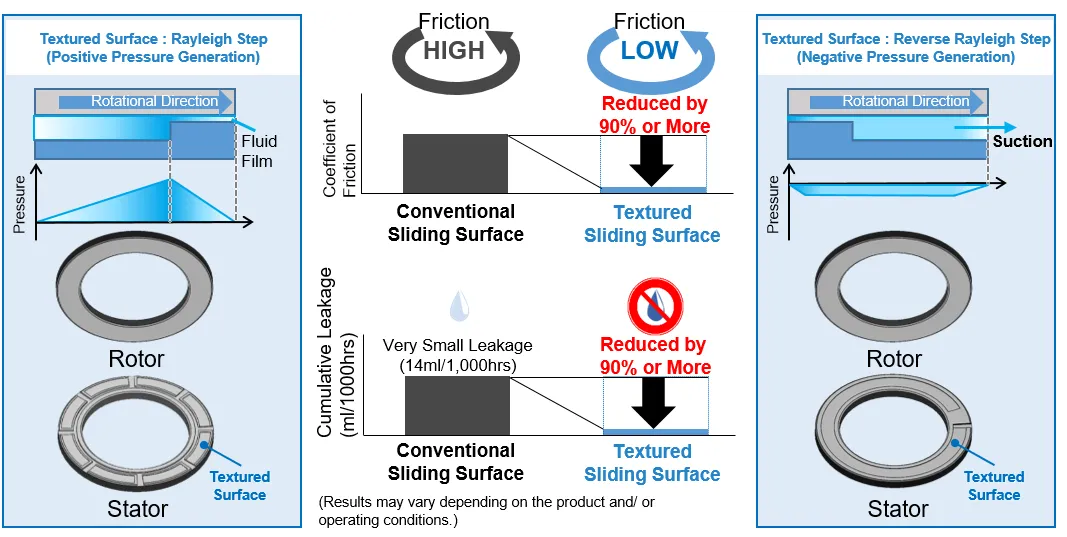

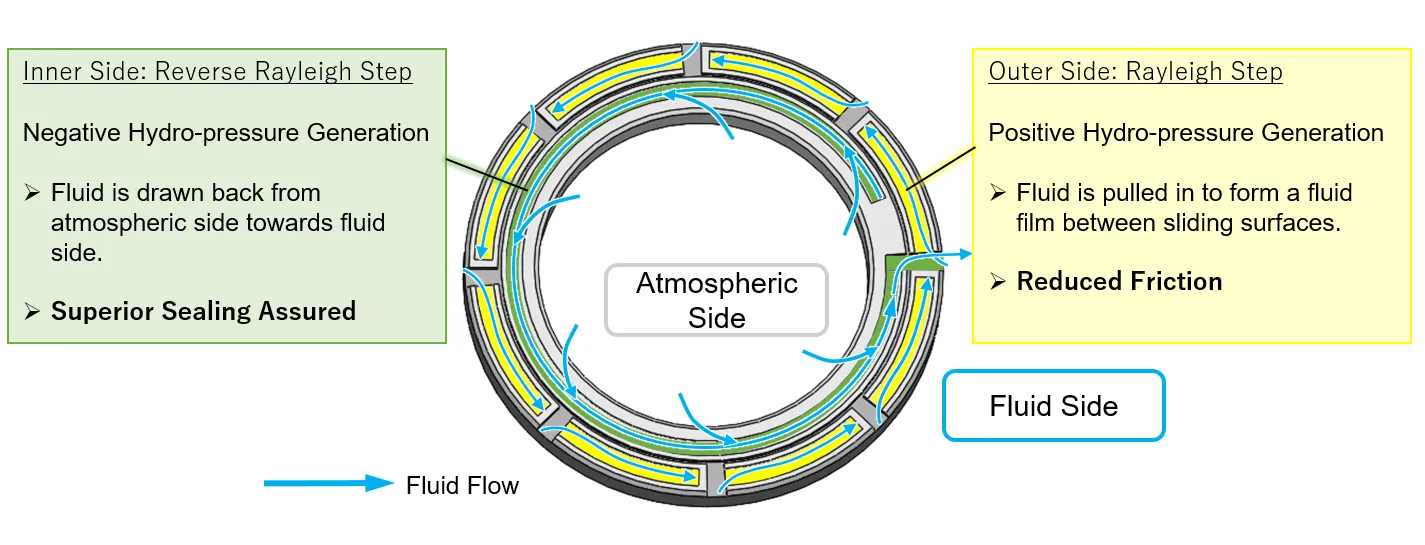

Pressure and leakage control

A textured surface is an uneven, micro structure that is processed to the sliding component.

During rotation, fluid is drawn into the textured surface to generate positive pressures, promoting formation of fluid film and separation of the sliding surfaces. As a result, friction is reduced by 90% or more, compared to the conventional sliding surface.

Furthermore, an optimized texture can also generate negative pressures, preventing fluid leaking passed the sliding surfaces. This achieves leakage reduction of over 90%.

Example of surface texturing structure (liquid lubrication)

EKK is capable of optimizing the textured surface design for various functional requirements. By processing different, independent textures to the same sliding surface, multi-functional characterization can be realized.

Function of surface texturing structure (liquid lubrication)

EKK employs various numerical analysis and measuring techniques to design textured surfaces.

Illustrations below compare numerical analysis of the pressure profile and phenomenon observed between actual sliding surfaces.

As anticipated from the pressure analysis, fluid (droplets applied for observation) at the atmospheric side is drawn to the fluid side due to negative pressure generation between the sliding surfaces (i.e. pumping effect).

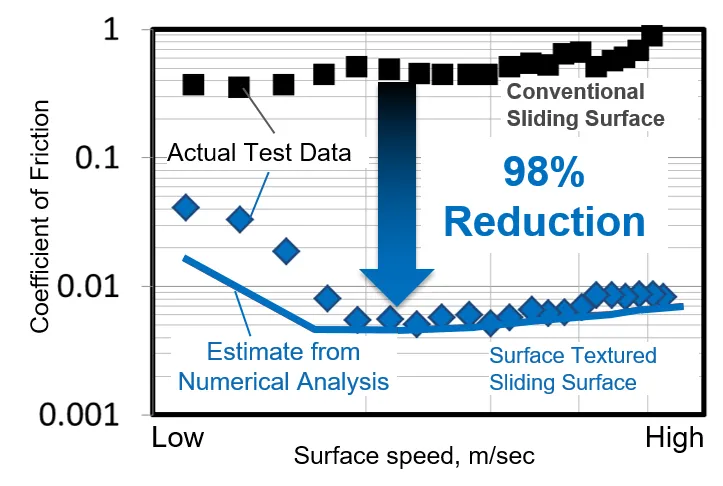

Friction reduction performance of surface texturing structure (liquid lubrication)

The graph below is an example of test results comparing coefficients of friction for conventional and textured sliding surfaces. Surface texturing is found to reduce friction up to 98%. At the same time, numerical analysis is validated with its close correlation to actual test data.

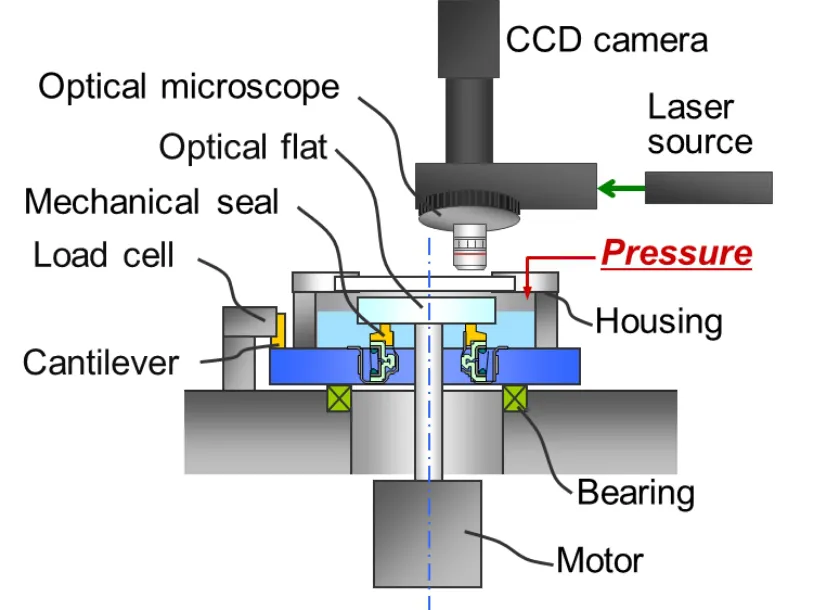

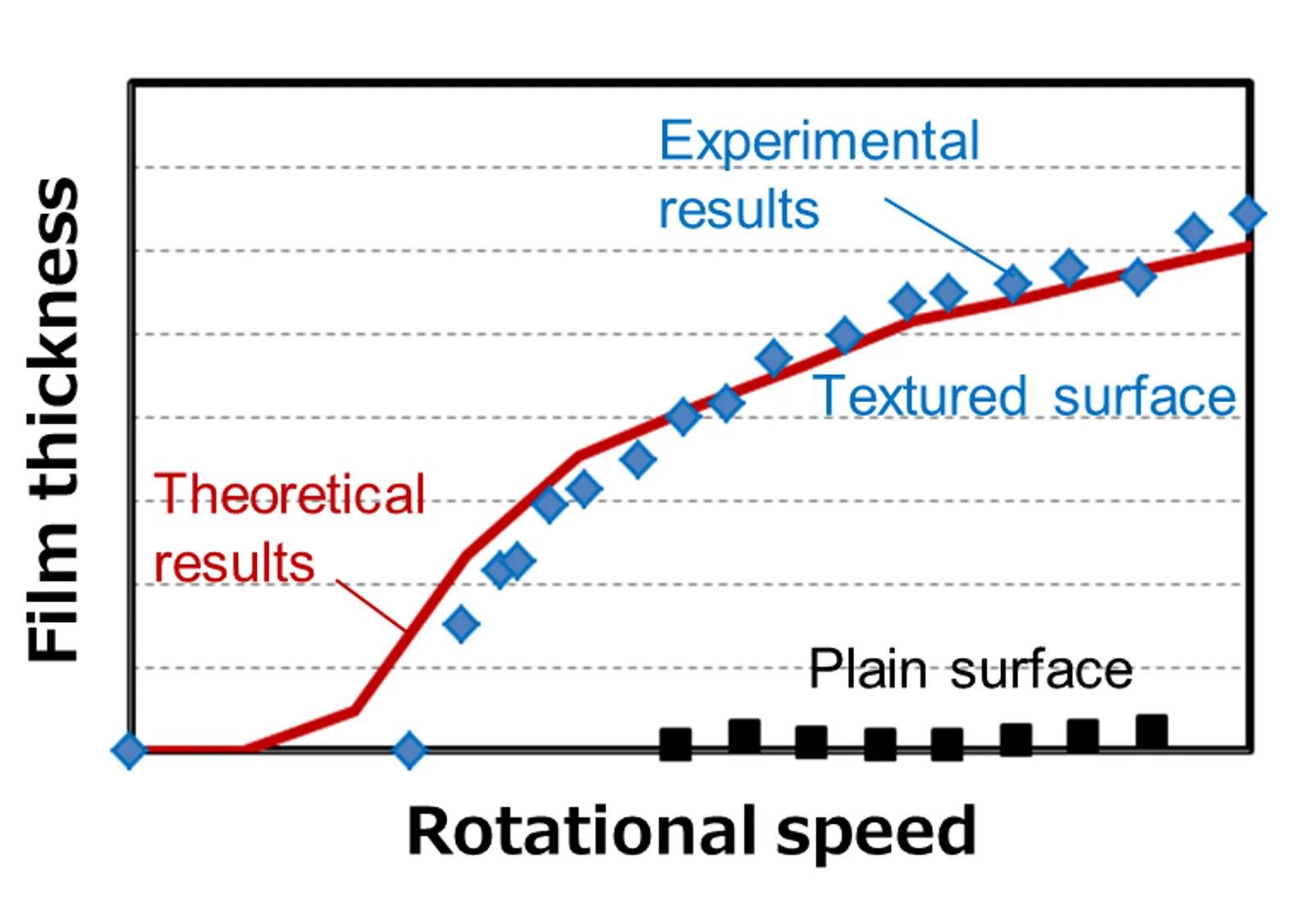

To evaluate the film thickness formation capability of mechanical seals, EKK has constructed a unique sliding surface visualization system using the laser-induced-fluorescence method (LIF method) to measure the film thickness between sealed surfaces. This system enables quantitative measurement and evaluation of the film thickness distribution between sliding surfaces of mechanical seals at rest and during rotation on the submicron order.

- Fluid film thickness measurement technology

- Flow visualization technology inside grooves using μ-PIV

The film thickness measurement results show that the surface textured seal forms a fluid film thickness of around 1 μm, which is in good agreement with the numerical analysis results. This indicates that the fluid lubrication function of the surface textured seal can be accurately predicted by numerical analysis.

Various numerical analysis and measurement technologies are employed in the surface texturing design process.

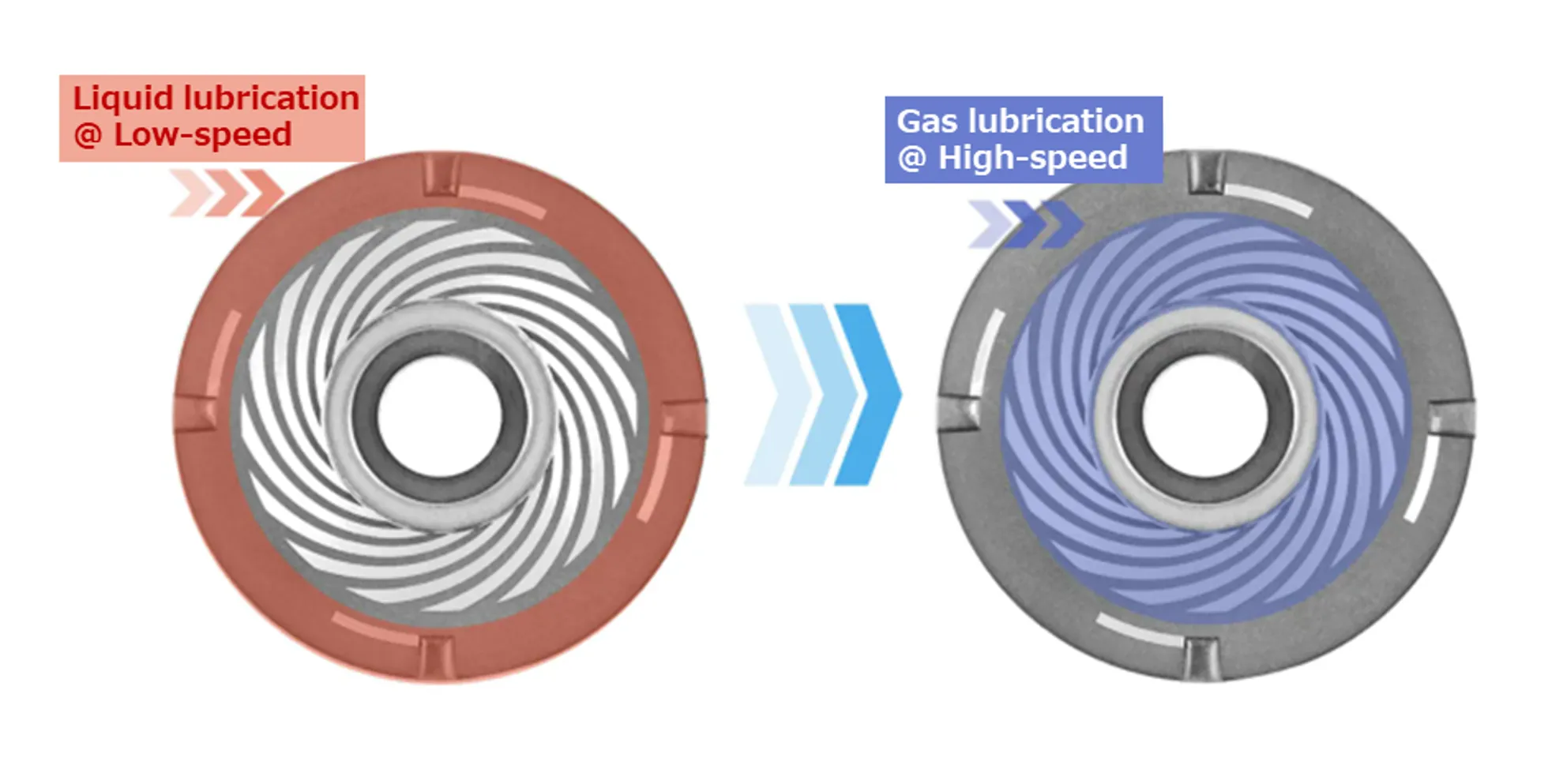

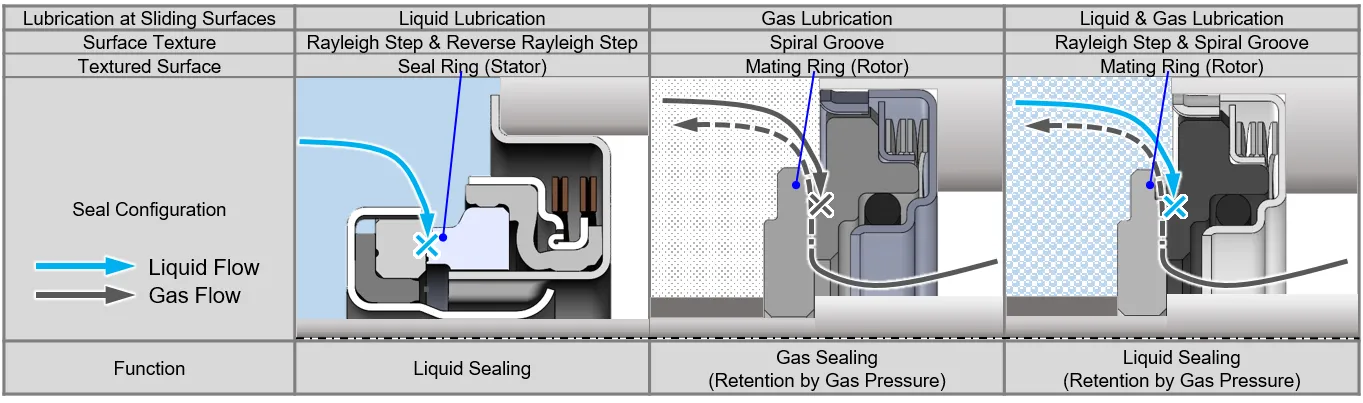

Example of surface texturing geometry (gas-liquid hybrid lubrication)

At high rotational speeds, fluid friction due to the viscosity of the liquid may be significant and cannot be ignored, even in the case of a non-contact seal using liquid lubrication. Therefore, we have proposed and put into practical use the world‘s first surface texture shape that can realize gas-liquid hybrid lubrication, which covers a wide range of rotational speeds from startup to ultra-high speed rotation by automatically switching to liquid lubrication during startup and stop and to air lubrication during ultra-high speed rotation. The basic configuration is the same as that of liquid lubrication, with lubrication grooves on the outer circumference (high pressure side/red area) and pumping grooves on the inner circumference (low pressure side/blue area), differing only in that the pumping groove on the inner circumference also has a gas lubrication function. During start/stop and at low speed immediately after the start of rotation, the machine operates in a liquid-lubricated state due to the Rayleigh step located on the outer circumferential side (high pressure side) of the sliding surface. No leakage occurs because the liquid is drawn back to the high pressure side by the spiral grooves located on the inner circumference side (low pressure side). During high-speed rotation, the spiral grooves on the inner circumferential side draw air into the sliding surfaces. As a result, the liquid introduced at low speeds is completely eliminated from the sliding surfaces, resulting in a completely gas-lubricated state. The air lubrication, which has extremely low viscosity, is the main component of the lubrication, enabling operation with ultra-low friction at high speeds.

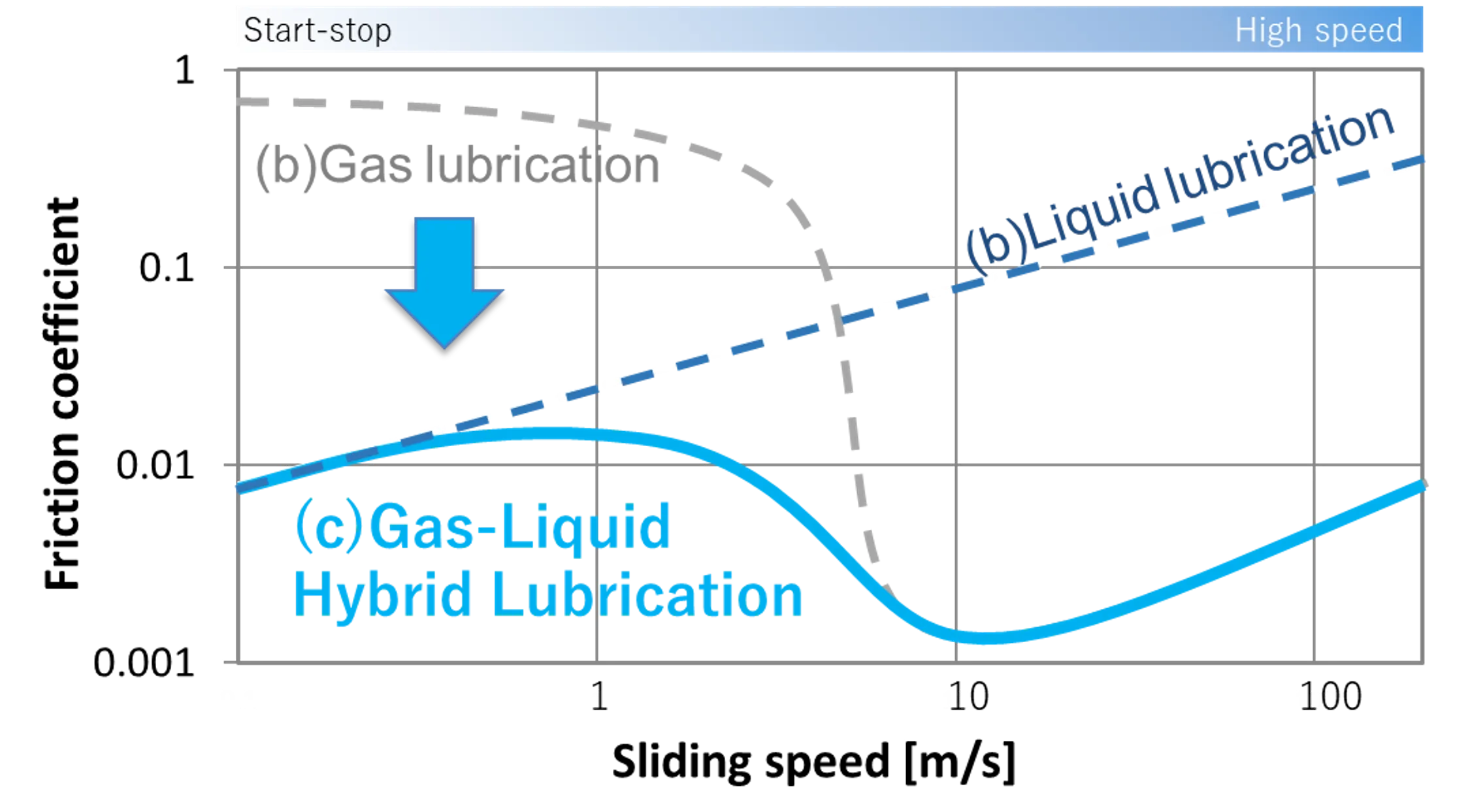

The figure on the right illustrates the friction characteristics of gas-liquid hybrid lubrication. With liquid lubrication, the coefficient of friction is relatively low at low speeds, but increases with increasing speed (a). In contrast, with gas lubrication, the coefficient of friction is very high at low speeds but dramatically decreases at high speeds (b). In a gas-liquid hybrid lubricated seal, as speed increases, centrifugal force and other factors cause the liquid lubricating film between sliding surfaces to be eliminated and replaced by gas, resulting in an automatic transition from a liquid-lubricated to a gas-lubricated state. This is designed to achieve low friction from low speed to ultra-high speed rotation (c).

This surface texture geometry has been put to practical use mainly in high-speed applications such as shaft cooling seals for EVs and gearbox seals for e-Axle.

Seal Characteristics by Application

Utilizing surface texturing technology, EKK is capable of offering optimized solutions for various operating conditions and functional requirements. In any cases, EKK achieves over 90% reduction in torque, compared to conventional mechanical seals, while ensuring superior sealing performance. For conventional seals, maximum speed approaching 50m/s could be attained without significant leakage. However, surface textured seals may be applied beyond this speed limit with uncompromised fluid sealing.

Application examples of surface texturing technology

EKK’s surface texturing technology is already being applied in a variety of fields.

Automotive Industry

General Industrial Machinery

Semiconductor Manufacturing Equipment

Marine & Offshore Generators

Aerospace Industry

Award History

EKK has received the following awards in recognition of surface texturing technology and its applications.

Award History

- Excellent Poster Award, 2nd Tribology Autumn School 2011 in Kure, Japan, Japanese Society of Tribologists

- Encouragement Award 2014, Japanese Society of Tribologists

- Technology Award 2018, Japanese Society of Tribologists (NOK/EKK AT Seal Ring)

- Best Poster Award, 10th Tribology Autumn School 2019 in Aichi, Japan, Japanese Society of Tribologists

- 21st Tribo-PPRIME Workshop 2022 Michel Fillon Prize(Best Paper)

Published Papers and Bibliography

The following is a list of published literature on EKK’s surface texturing technology.

| Title | Presentation / First Author | Presentation / Submission to | Genre | Year |

|---|---|---|---|---|

| Recent developments in high speed mechanical seal applications with textured surface for e-motor shaft seals and cryogenic turbopumps | Y. Tokunaga | TRIBO-PPRIME 21st workshop, Proc. | Conference Presentation | 2022 |

| Advanced Surface Textured Mechanical Seal for Tidal Power Generator | EKK | Wave & Tidal Energy Network (Green Energy Publishing Ltd.) | Review | 2021 |

| Observation and pressure measurement of cavitation region in mechanical seal | M. Itadani | 25th International Conference on Fluid Sealing (BHRG2020), Proc. | Conference Presentation | 2020 |

| Dynamic Sealing with Ultra-low Friction for e-Drives | R. Dircks | CTI Symposium, Proc. | Conference Presentation | 2020 |

| Low-friction Sealing System for E-drives | H. Inoue | MTZ (Springer) | Review | 2020 |

| Development of Ultra-Low-Friction and Zero-Leakage Mechanical Seal for High-Speed e-Mobility Shaft Sealing Applications | Y. Tokunaga | WCX 2020 SAE World Congress Experience, Proc. | Conference Presentation | 2020 |

| Visualization of micro cavity flow of surface textured mechanical seal by Particle Tracking Velocimetry | I. Ou | STLE Tribology Frontiers Virtual Conference 2020, Proc. | Conference Presentation | 2020 |

| GlideX – frictionless sealing solution for electric drives | R. Dircks | Antriebstechnisches Kolloquium 2019, Proc. | Conference Presentation | 2019 |

| Sealing Performance of Surface Textured Mechanical Seal in Cryogenic Condition of Liquid Hydrogen on Rocket Engine Turbopump | Y. Tokunaga | International Tribology Coference Sendai 2019, Proc. | Conference Presentation | 2019 |

| Realization of Ultra-High Speed, Zero-Leakage and Low-Friction Textured Mechanical Seals by combining Liquid and Gas Lubrications – Gas Liquid Hybrid Face | W. Kimura | 20th International Sealing Conference Stuttgart 2018, Proc. | Conference Presentation | 2018 |

| Realisation of Zero-Leakage and Low-Friction Surface Textured Mechanical Seals for Tidal Turbine | Y. Negishi | 20th International Sealing Conference Stuttgart 2018, Proc. | Conference Presentation | 2018 |

| The Multi-Objective Optimization focused on the Pumping Action for Zero-Leakage and Low-Friction Texturing Mechanical Seals | H. Suzuki | 24th International Conference on Fluid Sealing (BHRG2018), Proc. | Conference Presentation | 2018 |

| Realization of Surface Textured Mechanical Seals for Tidal Turbine | Y. Negishi | 6th International OTEC Symposium, Proc. | Conference Presentation | 2018 |

| Recent developments in zero-leakage and low-friction mechanical seal with textured surface | Y. Tokunaga | 17th EDF/Pprime Workshop, Proc. | Conference Presentation | 2018 |

| The Optimization of Dimple-Arrangement for Sealing and Lubrication Characteristics on Mechanical Seal Surface | T. Imura | World Tribology Congress 2017 Beijing, Proc. | Conference Presentation | 2017 |

| Multi-objective design optimization for zero-leakage and low-friction mechanical seals with surface texturing | Y. Tokunaga | World Tribology Congress 2017 Beijing, Proc. | Conference Presentation | 2017 |

| Improvement in sealing performance and friction reduction by laser surface tesxuring for mechanical seal | Y. Tokunaga | 21st International Conference on Fluid Sealing (BHRG2011), Proc. | Conference Presentation | 2011 |

| Sliding characteristic of silicon carbide under water-lubricated conditions | Masao Oka | Proc. World Triboloby Congress 2009 | Conference Presentation | 2009 |

| Corrosion Resistance of Plasma-Oxidized Stainless Steel | Jiro Okado | SURFACE AND COATING TECHNOLOGY | Research Paper | 2008 |

| Measurement of film distribution by two-dimensional dynamic measuring system for mechanical seals | Y. Tokunaga | 19th International Conference on Fluid Sealing (BHRG2007), Proc. | Conference Presentation | 2007 |

| Formation process of low friction interface in plane contact of SiC sliding against itself in water | Takuto Fukuhara | Proc. International Tribology Coference Sendai 2019 | Conference Presentation |